Upgrading to silicone hoses may seem like a minor tweak, but for racing enthusiasts and mechanics, it’s an essential enhancement. Stock rubber hoses, while affordable, often struggle under the pressure of high-performance driving. If you’re looking to boost your car’s reliability, prevent costly breakdowns, and increase the longevity of your system, silicone hoses are the ultimate upgrade. Let’s explore why these hoses have become the go-to choice in the automotive world.

Silicone hoses outperform rubber hoses in critical areas like temperature resistance, durability, and flexibility. They can withstand extreme temperatures, resist degradation from chemicals and UV rays, and are highly durable under pressure. This makes them the perfect solution for racing cars, where engine demands are higher and reliability is crucial.

Why Are Silicone Hoses Better?

Silicone hoses are made from high-quality silicone rubber, a synthetic material that offers superior resistance to extreme temperatures, weathering, and UV exposure. This makes them an ideal choice for high-performance vehicles, where engines run hotter and are exposed to more extreme conditions.

One of the biggest drawbacks of rubber hoses is their tendency to crack, swell, or degrade when exposed to extreme heat or chemicals. Over time, this deterioration leads to leaks, reduced performance, and even engine failure. Silicone hoses, however, are designed to endure these challenges, maintaining their structure and flexibility even under harsh conditions.

For mechanics working on race cars or heavily modified street cars, this enhanced durability means fewer replacements and less downtime, both of which are critical when every second counts on the track.

Do Silicone Intake Hoses Make a Difference?

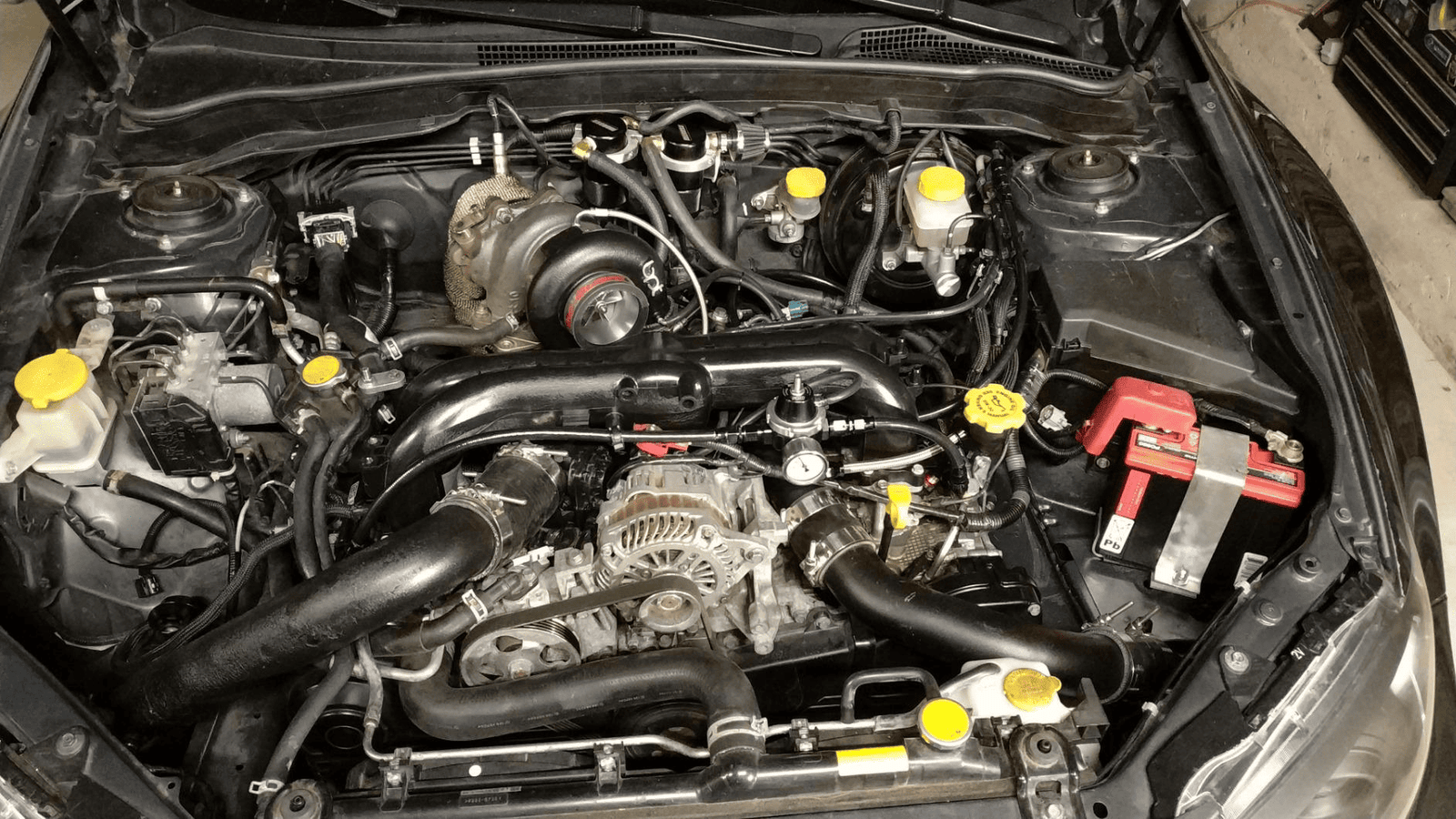

When it comes to high-performance engines, silicone intake hoses make a noticeable difference. Intake hoses play a crucial role in delivering cool, clean air to the engine, a process that is essential for optimal performance. The problem with rubber hoses is that they tend to expand and contract with temperature fluctuations, which can reduce airflow and create inconsistencies in engine performance.

Silicone hoses, on the other hand, are designed to maintain their shape and integrity even in extreme conditions. They can withstand higher temperatures without expanding or weakening, which ensures that the engine receives a steady supply of air under all conditions. This is especially important in racing cars, where maintaining peak performance is critical to success on the track.

In short, upgrading to silicone intake hoses helps to stabilize airflow, improve engine performance, and reduce the risk of damage caused by temperature-induced expansion and contraction.

Do Silicone Hoses Improve Performance?

Silicone hoses improve performance in a number of ways, particularly in vacuum and high-pressure applications. One of the biggest advantages of silicone hoses is their ability to handle high pressures without collapsing or deforming, which is a common issue with rubber hoses. This consistent performance under pressure ensures that fluid or air is transported efficiently through the engine, which in turn helps to optimize overall engine performance.

For racing enthusiasts, the ability to maintain consistent performance under high-stress conditions is critical. Whether you’re pushing your car to its limits on the track or simply want the peace of mind that comes with a reliable, high-performing engine, silicone hoses are a clear winner.

What Are the Benefits of Silicone Tubing?

Silicone hoses offer a wide range of benefits beyond just improved temperature resistance and durability. Flexibility is another key advantage that silicone hoses have over rubber. While rubber hoses tend to become stiff and brittle over time, silicone hoses maintain their flexibility throughout their lifespan. This makes them easier to install, especially in tight engine bays where precision is important.

Another important benefit is vibration absorption. Silicone hoses are excellent at absorbing vibrations from the engine, which reduces wear and tear on other components. This is particularly beneficial in racing applications, where engines are subjected to intense forces and vibrations that can cause damage over time.

Additionally, silicone is highly resistant to chemicals and fluids. Whether it’s oil, coolant, or other automotive fluids, silicone hoses are much less likely to degrade compared to their rubber counterparts. This resistance to chemical breakdown means that silicone hoses last longer and perform more consistently, even in harsh conditions.

Silicone Radiator Hoses vs. Rubber: Which One Should You Choose?

When it comes to choosing between silicone and rubber radiator hoses, the decision often comes down to the specific needs of the vehicle and driver. Rubber hoses are standard in most production cars because they are inexpensive and easy to manufacture. However, they come with a significant downside: they degrade quickly under extreme conditions, which can lead to leaks, overheating, and engine damage.

Silicone radiator hoses, on the other hand, are designed to handle higher temperatures and pressures without losing their shape or functionality. This makes them ideal for racing cars, where the cooling system plays a crucial role in keeping the engine running smoothly.

While silicone hoses are more expensive upfront, their durability and reliability make them a worthwhile investment for anyone who takes their vehicle’s performance seriously. In the long run, fewer replacements and less maintenance can offset the initial cost, making silicone hoses a smart choice for both casual enthusiasts and professional mechanics.

What Are the Disadvantages of Silicone Hoses?

Despite their many advantages, silicone hoses do have some drawbacks that should be considered. One of the most significant disadvantages is that they require special hose clamps. Because silicone hoses are more flexible than rubber hoses, they can be prone to slipping if the wrong type of clamp is used. Specialized clamps are required to ensure a secure fit, which adds to the overall cost of the upgrade.

Another potential issue is porosity. Silicone is a porous material, which means that it can allow small amounts of air or fluid to pass through over time. For most applications, this isn’t a problem, but in situations where an airtight or fluid-tight seal is critical, silicone hoses may not be the best choice unless they are lined with another material.

Finally, cost is a factor. Silicone hoses are more expensive than rubber hoses, which may be a barrier for some drivers. However, for those who prioritize performance, reliability, and durability, the benefits of silicone hoses far outweigh the higher cost.

How to Properly Maintain and Install Silicone Hoses

Proper installation and maintenance are crucial to getting the most out of your silicone hoses. Always make sure to use the correct hose clamps to prevent leaks and ensure a secure fit. During installation, check that the hoses are properly aligned and free from any kinks or bends that could restrict airflow or fluid movement.

It’s also important to inspect silicone hoses regularly for any signs of wear, especially after high-performance events like races. While silicone hoses are highly durable, they aren’t completely immune to damage, and regular inspections can help catch any potential issues before they become serious problems.

Conclusion

For racing enthusiasts, mechanics, and those in the market for performance parts, upgrading to silicone hoses is a smart investment. With superior temperature resistance, flexibility, and durability, silicone hoses are built to withstand the intense demands of high-performance driving. While they may cost more upfront, their longer lifespan and improved performance make them a worthwhile upgrade for anyone serious about enhancing their vehicle’s reliability and efficiency.

Whether you’re upgrading your radiator, intake, or vacuum hoses, silicone hoses are the ultimate choice for anyone looking to push their vehicle to its limits.