Silicone Hose manufacturer from 2001

Our factory has 23 years of production and design experience

Support OEM/ODM

Production

24500 m² of production area,190+employees,40000+ piece/month output,Large Product Range.

Solution

kinglin offers a comprehensive range of silicone rubber product solutions to meet the unique needs of various industries

Quality

One year Guarantee. Product certification, safety and security. Comply with SAEJ20 standard, strict production, ensure quality.

Wholesale Silicone Hose Products

Our products adhere to the strict product quality standards of ISO 9001:2015 and IATF 16949:2016.

Support OEM/ODM

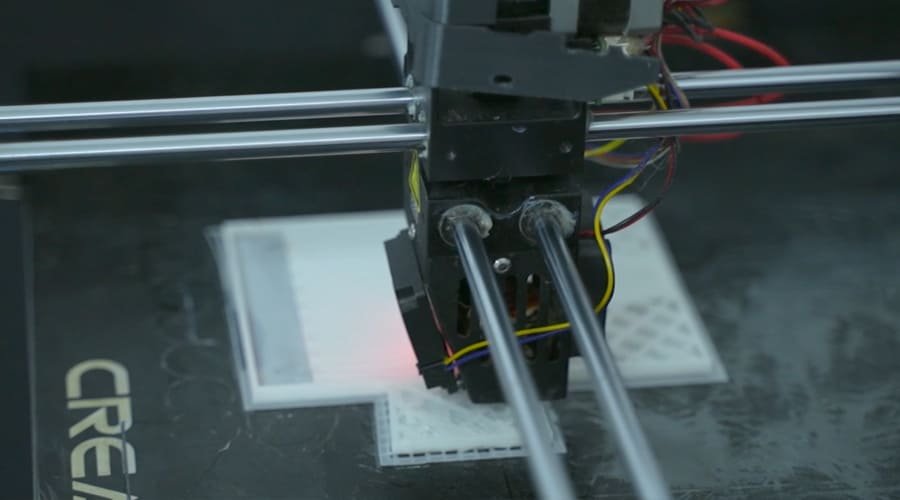

As a manufacturer with a complete production line, state-of-the-art equipment, and testing capabilities, we place great emphasis on research and development.

If our standard tubes don’t fit your needs, we can customize the hose to meet your required specifications.

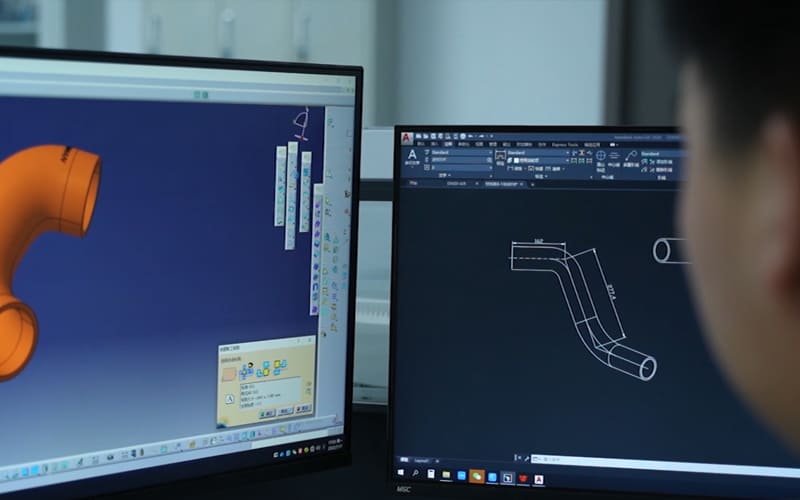

Custom Design and Engineering

Our team uses advanced design software like CAD, CATlA, and UG to create precise slicone hose designs. This aows us to customize hoses in all kinds ofshapes, sizes, and configurations to fit your specific needs.

Material Customization

We can customize the silicone material itself to give you better performance characteristics such as heat resistance, chemical resistance, and durability. We can use standard silicone, fluorosilicone for better oil and fuel resistance, or other specialty materials.

Reinforcement Options

Depending on the application's pressure and temperature requirements, we can reinforce hoses with polyester, aramid, or other fabrics, Thiscustomization ensures that hoses can handle the working pressures and burst pressures required, while remaining flexible and durable.

Other Customization Options

Customize product packaging, logo, etc. lf you need other customized solutions, please contact us!

Partners You Can Rely On

Hebei kinglin was established in 2001 and is located in Hebei Province. It is a silicone rubber hose manufacturer with complete production lines, complete equipment, and strong testing capabilities.

The factory covers an area of 16,000 square meters, a production area of 24,500 square meters, and a monthly output of more than 400,000 pieces. Our product line includes silicone hoses, rubber hoses, sealing strips, clamps, aluminum tubes, etc., focusing on serving automobiles, racing cars, modified cars, trucks, agricultural machinery, ships, and other fields.

With advanced production equipment and complete testing equipment, as well as a professional product development team, we continue to develop and design new products to meet the unique needs of our customers.

Adhere to ISO9001, IATF16949 quality management system, and ISO14001 environmental management system to ensure the stability and reliability of our product quality.

More Than Just a Silicone Hose Manufacturer

Hebei Kinglin is a manufacturer with complete production lines, professional design capabilities, advanced equipment and quality inspection systems. Our commitment to exceeding standard products and providing a high level of customer service sets us apart in the industry.

Personalized Solutions

With more than 20 years of OEM and ODM experience, and a professional design team, we can turn your ideas into reality.

If you need help with your design, our professional design team can recommend and design suitable hoses according to the specific application of your project. We will be responsible for everything from manufacturing to shipping and after-sales to ensure that you get the high-quality products you ordered in a timely manner.

High Quality Raw Materials

We select high-quality silicone and cloth raw materials and pass strict chemical analysis and mechanical performance tests to ensure the product’s high-temperature resistance, aging resistance, and other properties.

Our testing process ensures that each batch of silicone hoses meets customer demand for products.

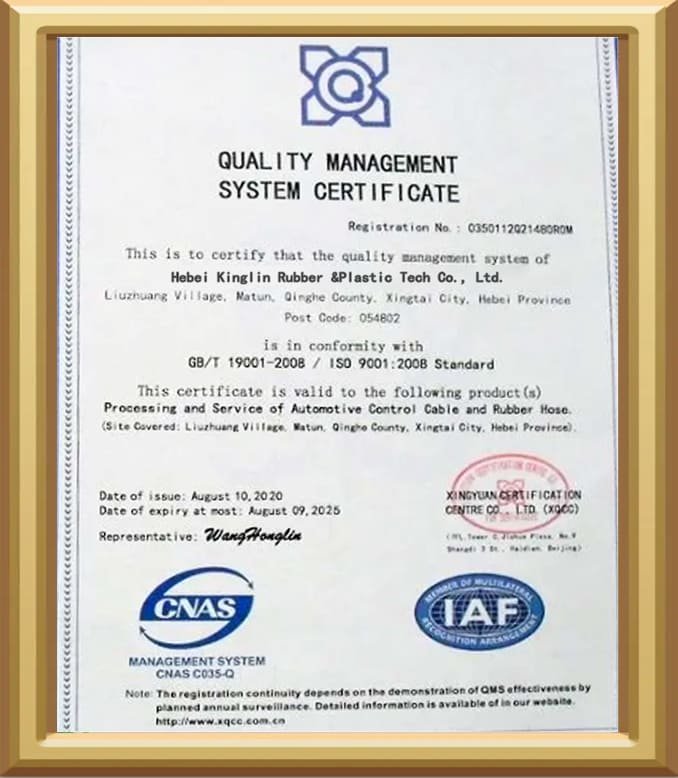

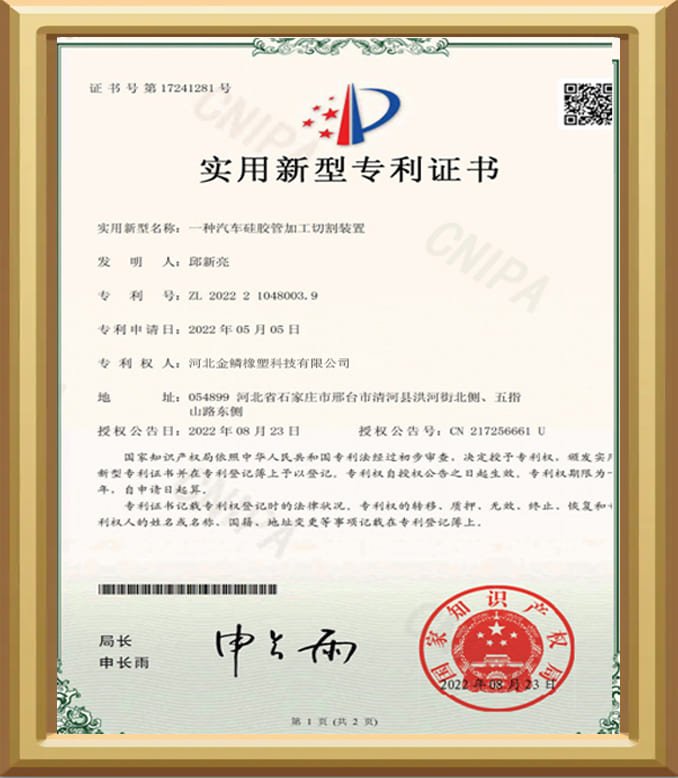

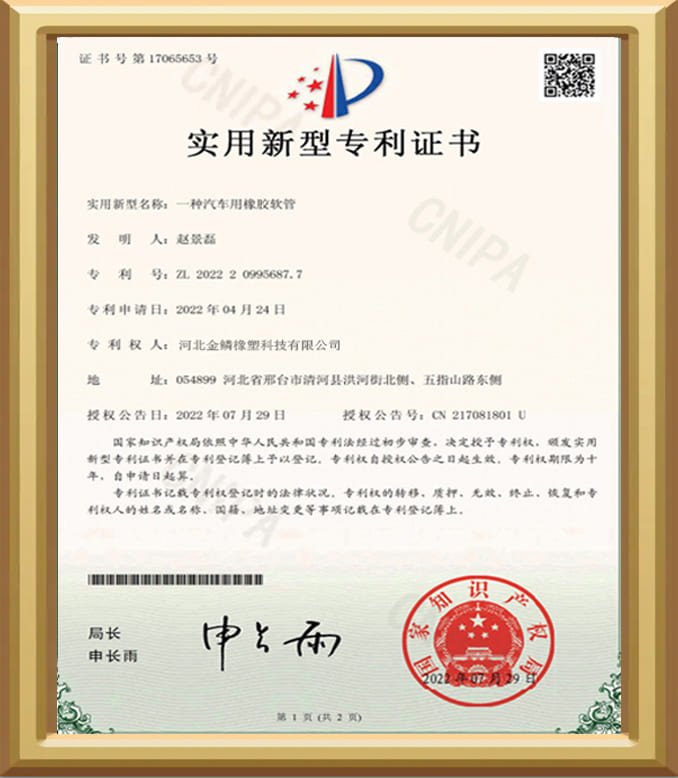

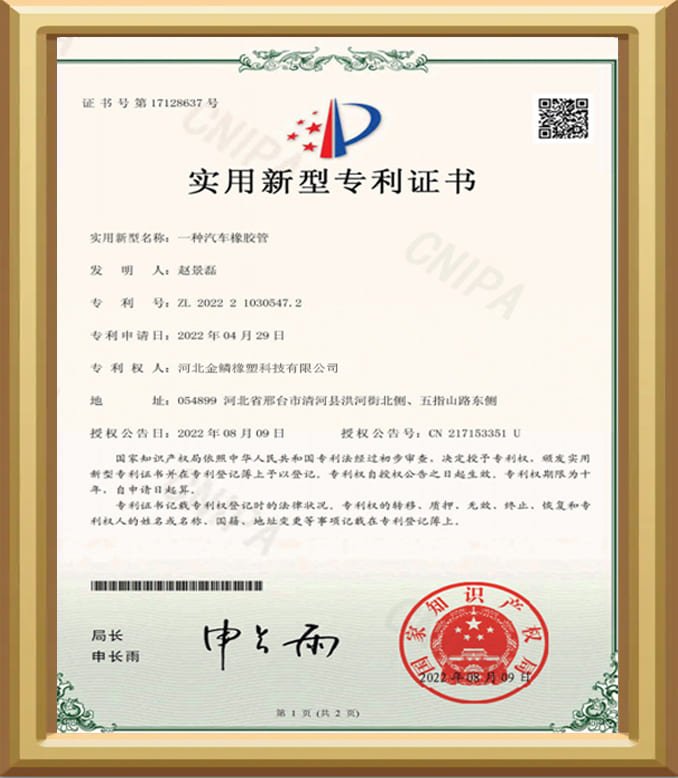

Product Certificate

We are a professional manufacturer of silicone hoses. We have IATF16949, ISO9001 quality management system, ISO14001 environmental management system certification and 8 patent certificates.

Our silicone hoses meet SAE J20 R1 Class A standards and implement strict quality control throughout the production process.

Delivery Fast

We have more than 190 skilled workers. Our rich experience and scale enable us to efficiently handle large orders, ensuring a stable supply of more than 400,000 pieces per month.

The factory has developed a semi-automated production process and cooperates with efficient logistics partners to ensure that we can deliver quickly, both in China and around the world, and each hose is carefully packaged to ensure that it arrives intact.

Quality Assurance

Our factory is equipped with professional quality testing equipment to ensure that every product meets the requirements

Our testing equipment

Tensile test, Salt spray test, Water pressure test, High temp-low temp test, Tearing test, Bursting pressure test, Aging test, Density test, Hardness Test, Oil Immersion, etc

100% inspection before delivery

After-Sales Follow-Up

Our relationship with our customers does not end with the successful delivery of the product, in fact, it is just the beginning, we believe in building lasting relationships.

we have an entire after-sales team that will follow up with you to ensure our service and Product exceed all your expectations.

Contact us 24×7 to solve all your after-sales problems.

We Have Always Been Customer-Focused And Solution-0riented

kinglin’s products have been sold all over the world, including more than 120 countries and regions in Europe, North America, South America, Asia, Australia, and the Middle East. Our silicone hoses have also been well-received by many customers.

Quality Control System

Our professional team will inspect all aspects of the products. Rest assured knowing quality control is our top priority.

We are equipped with advanced equipment to test the performance and quality of our products from multiple dimensions.

This comprehensive laboratory testing is conducted by skilled professionals to confirm that silicone tube products meet specifications.

Testing may include measuring tensile strength, breakage Elongation, and wear resistance, burst pressure, anti-aging and weathering, etc.

1. During the manufacturing process, the quality of the inner and outer glue is inspected, and there are multiple checkpoints to ensure that each step of the process meets predefined standards

2. Workers are in production: self-inspection by operators, mutual inspection by team leaders, and inspection by inspectors. If problems are found, 8D reports will be made to analyze, identify, and solve the problems.

2. Mixing and kneading: test the consistency and quality of the silicone rubber mixture, and monitor parameters such as film layer thickness

3. Extrusion and molding: When forming the hose, perform dimensional inspections (such as inner diameter, and wall thickness) to ensure compliance with requirements

4. Vulcanization process: The inspector checks the vulcanization time and temperature every day to ensure the best physical properties of the hose. After vulcanization, the hose is visually inspected to see if it meets the specifications. If it is found to be unqualified, it will be stopped as soon as possible and the cause will be investigated to implement rectification measures.

5. Cleaning inspection: After cleaning the silicone hose, the quality inspector will check the surface of the hose one by one for defects, irregularities, and consistency.

Visual inspection: Our production staff directly inspect the products one by one with the naked eye for damage, deformation, discoloration, etc.

3D tooling and dimensional inspection: After the silicone hose is completed, 3D tooling inspection and dimensional inspection will be carried out to ensure that all hose dimensions meet the customer’s specific requirements.

Send sample for inspection:

After the production is completed, we will send the sample to the customer for inspection. After the customer confirms that it is correct, mass production will begin.

1.Packaging factory quality control

Before packaging, the hoses undergo a final inspection to ensure that no defects have appeared during handling

2.random sampling

After passing all stages of inspection, samples from each batch are randomly selected and tested again to ensure consistency and quality.

Certificates Worth You Trust

On the premise of quality control, we maximize productivity and 100% quality inspection, not making any concessions on the quality in any step, from production to shipment.

Specialist Industries

We have manufactured millions of hoses for a wide variety of applications, but we are particularly knowledgeable in these areas.

Automotive Industry

Construction and Heavy Machiner

Ship Application

Truck Application

Customer Satisfaction

Check out our customer testimonials below:

Order & Payment

Frequently Asked Questions

If you have any questions, please feel free to contact us so that we can serve you a better product or service. We also warmly welcome you to share your expertise, let’s create an open space for exchange and learning for everyone passionate about the silicone hose industry.

Yes, kinglin is a factory with 23 years of production and export experience. Our factory is located in Qinghe County, Xingtai City, Hebei Province. Welcome to visit our factory

The minimum order quantity is different for each product, please contact us for details

Yes, we can customize product size, shape, color, logo, packaging, etc., to meet the different needs of your application

yes,If you want a sample to test the quality, we can provide it free of charge

Contact us for a free sample

If you have any questions or request a quote, please send us a message. Our experts will get back to you within 2 hours and help you choose the right hose.