Silicone Hose Manufacturer

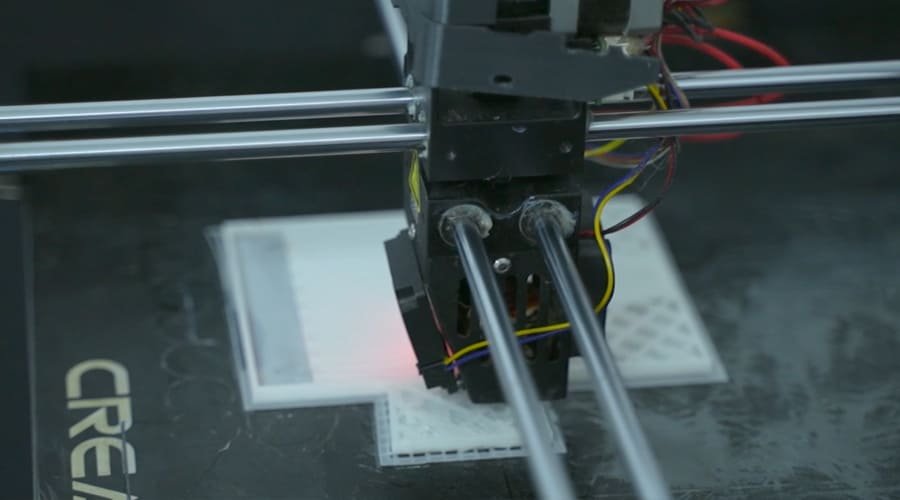

Kinglin was established in 2001, specializing in the research and development, manufacturing, and sales of silicone hoses and rubber hoses products.

At Kinglin, we are committed to innovation and quality, and our silicone hose products include standard silicone hose, truck silicone hose, extruded silicone hose, sleeves, and custom-designed solutions to meet the stringent needs of customers worldwide.

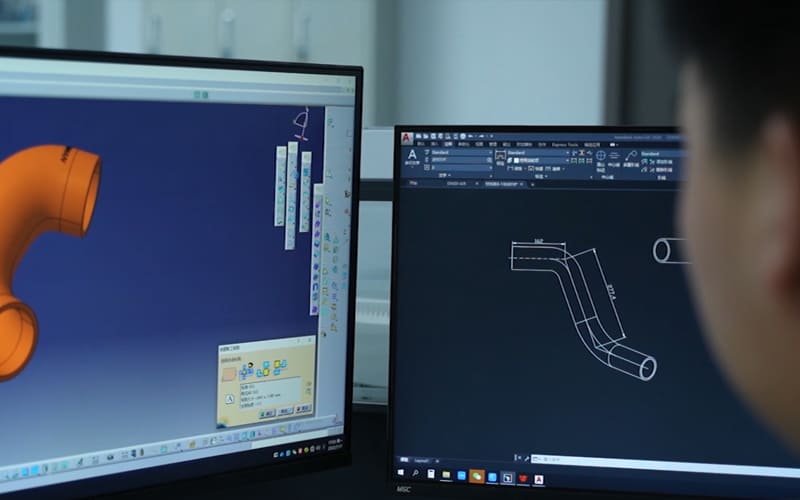

With our expertise in silicone hose manufacturing production, you can be confident that your ideas will quickly turn into a tangible return on investment.

Contact us today, we are here to help you