Truck Silicone Hose Manufacture

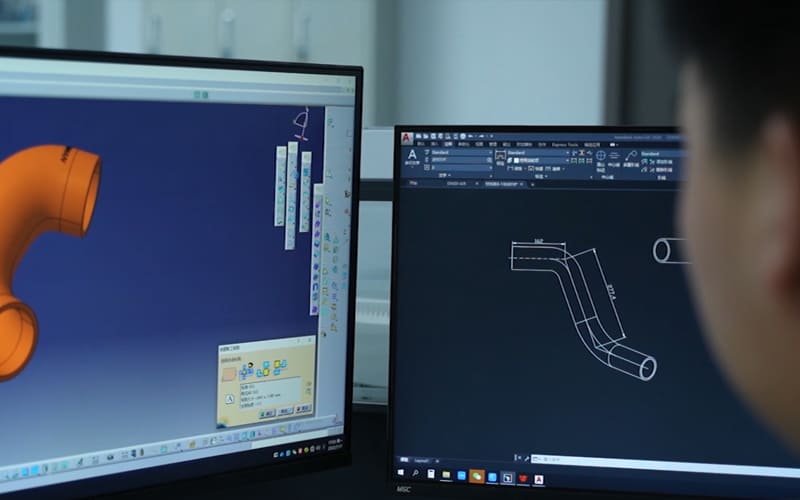

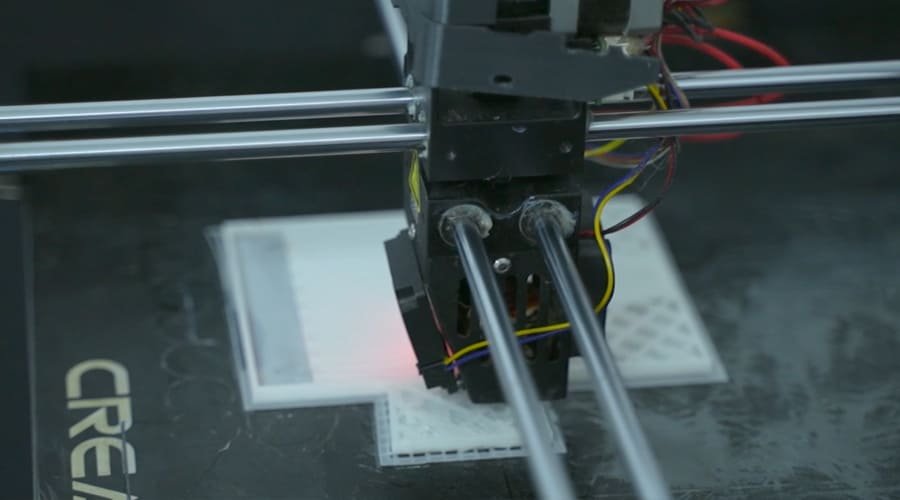

Founded in 2001, Kinglin specializes in the research, development, production, and sales of silicone and rubber hose products.

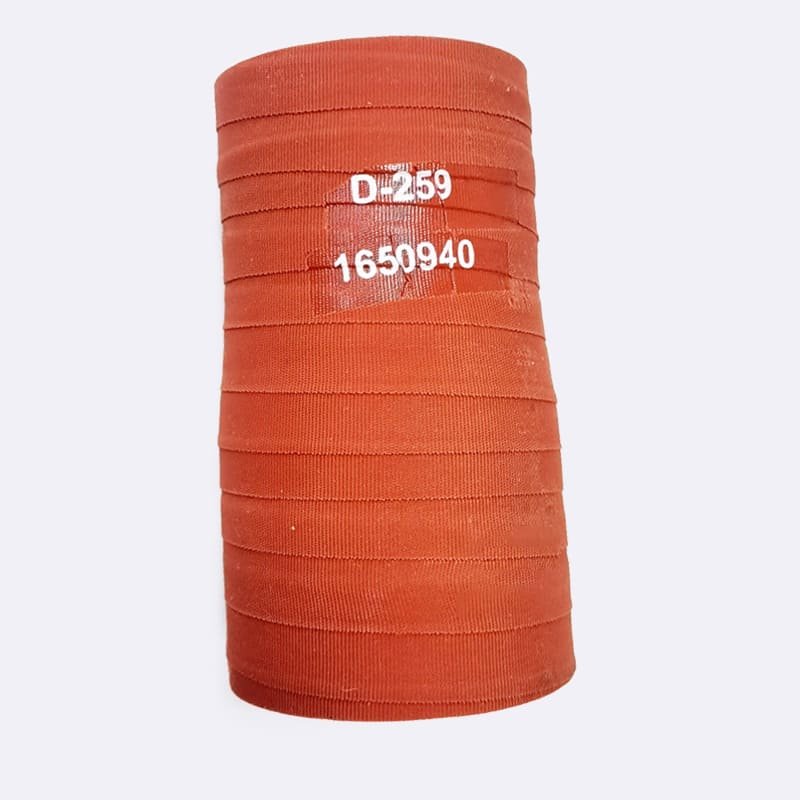

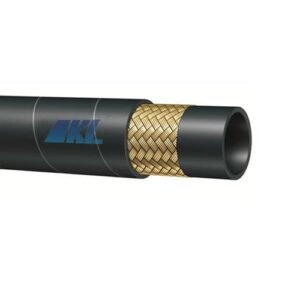

Committed to innovation and quality, Kinglin’s silicone hose product line includes standard silicone hoses, truck silicone hoses, extruded silicone hoses, silicone hose kits, rubber hoses, raidator hoses and custom hoses to meet your exacting needs.

With our expertise in silicone hose manufacturing and rigorous quality control, you can be confident that our dedicated team can help you achieve optimal market advantage.

Contact us today and we’re here to assist you.