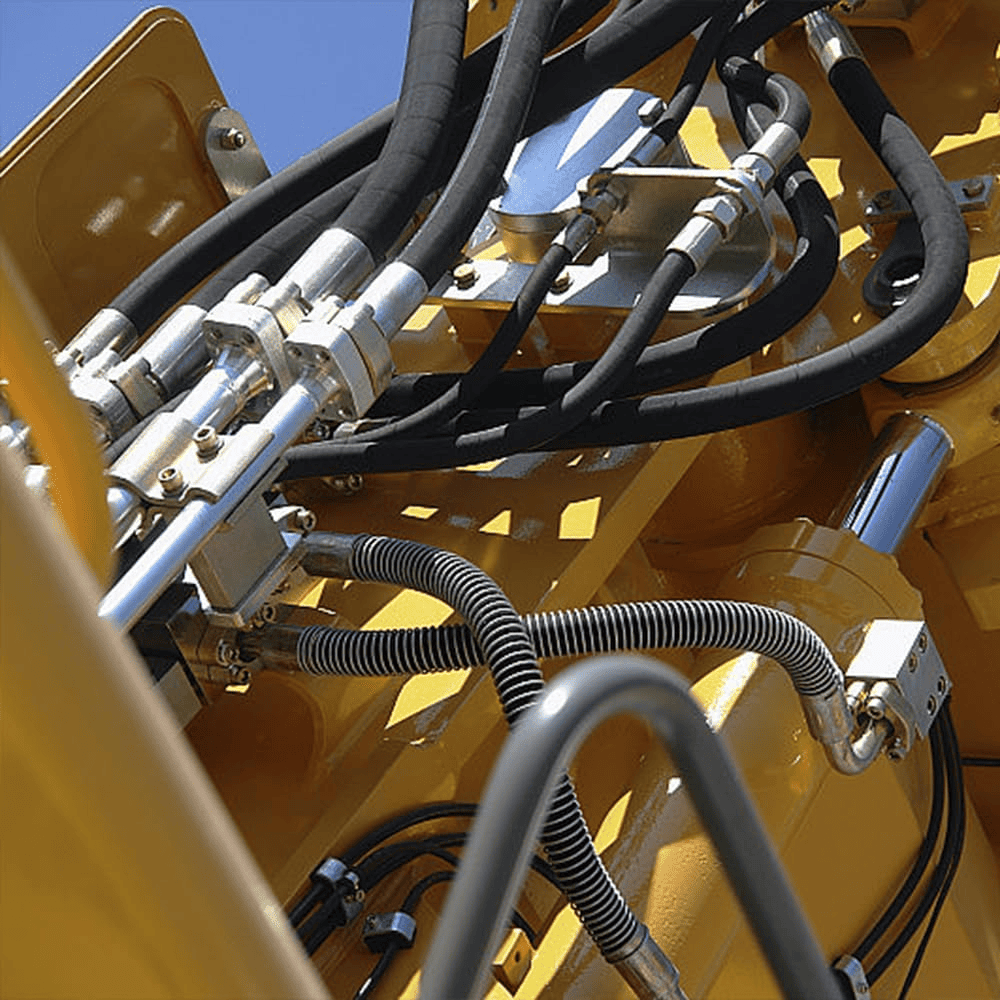

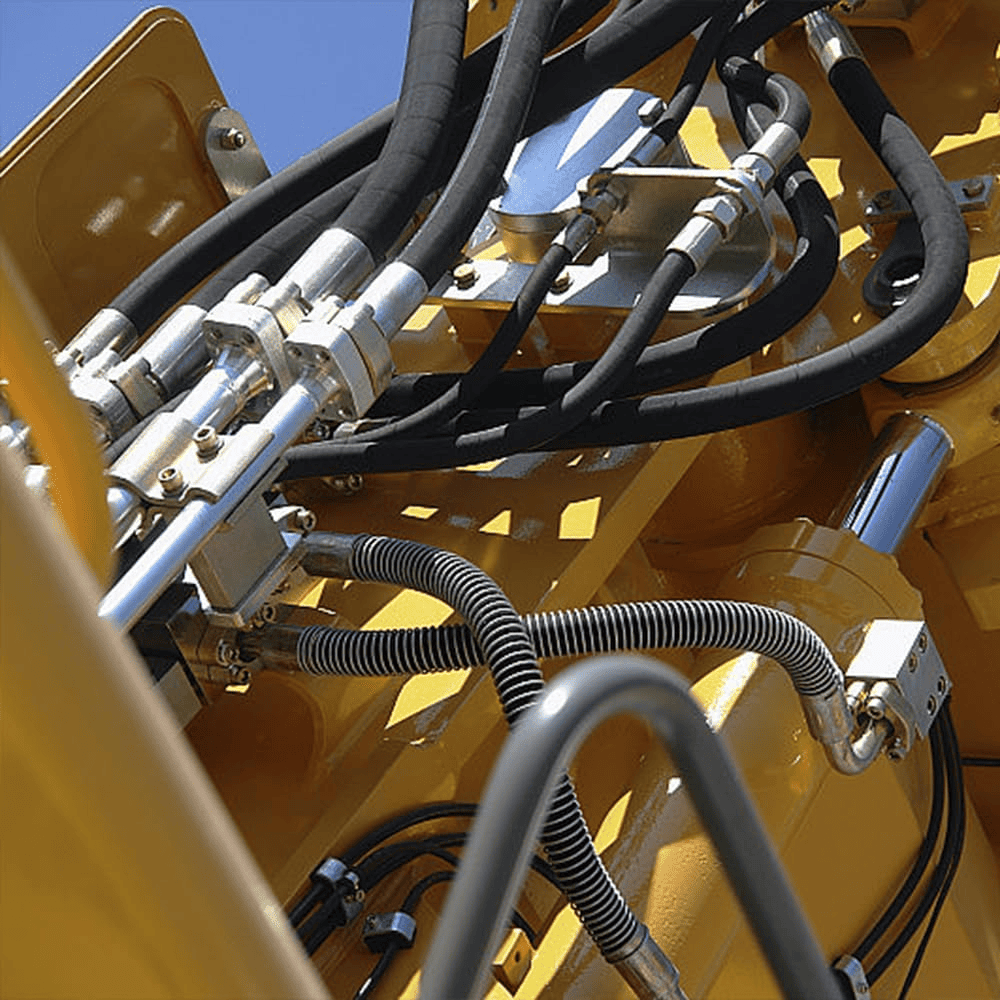

If you work with machinery, you’ve probably seen hydraulic hoses everywhere, whether on excavators, tractors, forklifts, or factory equipment. They may look like simple tubes, but they’re incredibly important.

In this guide, you’ll learn exactly what a hydraulic hose is, how it works, the materials and types available, and how to choose the right hose for your project.

What Is a Hydraulic Hose?

A hydraulic hose is a flexible, high-pressure tube that moves hydraulic fluid (usually oil or water) between parts of a machine. It connects pumps, valves, and cylinders, helping transfer energy so the machine can do work.

You can think of it like your body’s veins; they can give power to machines. Without hoses, the hydraulic system wouldn’t be able to move or lift anything.

Hydraulic hoses need to be strong because they deal with a lot of pressure — sometimes more than 10,000 PSI! That’s why they’re made with several layers of material to keep them safe and reliable.

The Parts of a Hydraulic Hose

Every hydraulic hose has three main layers:

- Inner tube – This is the core of the hose, where the hydraulic fluid flows. It must be compatible with the fluid type (oil, water, or synthetic). Common materials include synthetic rubber, thermoplastic, or PTFE (polytetrafluoroethylene).

- Reinforcement – This layer provides the hose’s strength. It is made of braided or spiral steel wire or textile reinforcement. Spiral reinforcement is used for very high pressures, while braided wire is used for flexible medium-pressure hoses.

- Outer cover – The protective layer of the hose. It protects the inner layer from weather, abrasion, chemicals, and UV rays. Most outer covers are made of synthetic rubber.

When you choose a hose, you are actually selecting a combination of these layers—the material, construction, and design need to match your application.

Hydraulic Hose Materials

Hoses can be made from different materials, depending on their operating environment, strength, flexibility, and compatibility with hydraulic fluid and water. Here are some common materials:

- Rubber: The most common and flexible type. Durable and affordable. They can handle a wide temperature range. They are well-suited for construction and agricultural machinery and suitable for most machines and outdoor equipment.

- Thermoplastic: Lightweight, non-conductive, and abrasion-resistant. These hoses work well in tight spaces or on mobile equipment where flexibility is important.

- PTFE: Can handle very high heat and chemicals. Used in food and chemical plants.

- Stainless steel: Ultra-rugged, designed for the harshest conditions, such as in factories or oil rigs.

Each material offers unique advantages. For example, if you work outdoors in extreme conditions, stainless steel or rubber may be your best choice. If you need a hose for a tight fit, thermoplastic is a better option.

Types of Hydraulic Hoses

There are many types of hydraulic hoses, but here are the main ones you’ll see:

- Rubber Hoses – Great for general use and flexible enough for most jobs.

- Thermoplastic Hoses – Lightweight, bendy, and strong, often used in tight spaces.

- Teflon (PTFE) Hoses – Resistant to heat and chemicals, great for harsh environments.

- Metal Hoses – Made of stainless steel, used when the hose needs to handle very high pressure or temperature.

When you buy hoses, look for manufacturer charts or guides that show the pressure rating, temperature limit, and fitting compatibility.

What Are Hydraulic Hoses Used For?

Hydraulic hoses are used in all kinds of machines. Here are some examples you might recognize:

- Construction: Bulldozers, loaders, and cranes.

- Farming: Tractors, plows, and harvesters.

- Factories: Press machines and assembly lines.

- Mining: Big drilling or lifting machines.

- Aviation and ships: To control mechanical parts safely and smoothly.

Basically, if a machine needs power to move, lift, or push, it probably uses hydraulic hoses.

What Are Hydraulic Hose Fittings?

Hose fittings are the metal ends that connect the hose to other parts of the hydraulic system, like pumps or cylinders. They’re super important because they keep the connection tight and prevent leaks.

There are a few main kinds of fittings:

- Crimp fittings: Permanent and strong. You’ll need a special crimping tool to install them.

- Reusable fittings: You can take these off and use them again. Handy for quick repairs.

- Push-lock fittings: Easy to attach, usually for lower-pressure systems.

Make sure your hose and fitting types match. Mixing the wrong ones can cause leaks or even accidents.

Hydraulic Hose Standards

When you buy hydraulic hose, you’ll often see codes like SAE 100R1AT or EN 853 2SN printed on the hose. These specifications tell you that the hose meets stringent international standards for performance and safety.

Here are the most common ones you’ll encounter:

- SAE J517: North American standard for hose performance.

- ISO 18752: International standard for hose pressure and temperature ratings.

- EN 853–857: European standards that cover hose design and testing.

These standards help make sure the hose you buy is strong, safe, and long-lasting.

What Is Hydraulic Fluid?

Hydraulic fluid is the liquid that flows through the hose. It transfers power and keeps the system cool and smooth.

Here are the main types of fluid you’ll see:

- Mineral oil: The most common and affordable type.

- Synthetic oil: Handles high temperatures and lasts longer.

- Biodegradable fluids: Safer for the environment, used in farming or marine systems.

Always check that your hose material matches the type of fluid you’re using. The wrong fluid can damage the inside of the hose.

How to Choose the Right Hydraulic Hose

If you need to buy or replace a hose, you can use the following method to make the right choice:

- Size: The inside diameter must fit your system.

- Temperature: Check how hot or cold your system gets.

- Application: Think about what kind of work the hose will do.

- Material: Choose a hose that works with your hydraulic fluid.

- Pressure: The hose has to handle your system’s maximum pressure.

- Ends: Make sure fittings are the right type and size.

- Delivery: Consider how long and flexible the hose needs to be.

For example, if you work on a farm, you’ll want a rubber hose that’s flexible and can handle dirt and weather. But if you’re working in a factory with hot fluids, a Teflon hose might be better.

Hydraulic Hose Maintenance Tips

Even though hoses wear out over time. To keep your system operating safely and efficiently, you need to regularly inspect and replace hoses. Here’s how to care for your hoses:

- Check for leaks or cracks often.

- Don’t twist or pull the hose too hard when installing it.

- Replace old or damaged hoses right away.

- Keep hoses clean so dirt doesn’t get into the system.

- Store hoses properly — out of the sun and away from heat.

Taking care of your hoses will help them last longer and keep your machines safe and running smoothly.

Summary

Hydraulic hoses are more than just hoses; they’re the vital power lines that keep your machinery running smoothly.

When you understand their materials, construction, types, standards, and maintenance, you can confidently and safely select the right hose.

If you need professional advice or would like to purchase hydraulic hoses in bulk, please contact us.

We provide durable, high-quality hoses to meet your exact requirements and keep your hydraulic system running reliably for years to come.