Bending silicone hoses incorrectly can result in cracks, kinks, and expensive replacements. Many installers struggle to find the safest, cleanest way to shape these durable components. Thankfully, with the right tools and a few smart techniques, you can create precise bends without compromising the hose.

To bend a silicone hose without damage, avoid forcing it. Instead, use a bending spring or coil inside the hose to maintain its shape during the bend. For tighter curves, gently heat the hose (if safe) and support it internally. Never apply abrupt pressure, which may cause kinks or cracks.

Next, let’s learn about the safest and most effective method of silicone hose molding

Can You Reshape Silicone Hoses Safely?

You may be tempted to use brute force or extreme heat to bend silicone hose, but these methods can cause long-term damage. Silicone is flexible, but it is not designed to be reshaped using high temperatures or excessive twisting. Some silicone hose manufacturers specifically advise against using a heat gun for bending because it can damage the hose.

Instead, bends should be made using techniques that preserve the hose structure and have low impact on the hose.

What Tools Help Bend Silicone Hoses Without Kinking?

Here are my favorite tools for bending silicone hoses:

- Bending Springs (Internal): These go inside the hose to keep it from collapsing as you bend it.

- Unicoil: A coil that wraps around the outside of the hose, letting you shape and hold the hose.

- Mandrel: For professionals, mandrels can be used to bend hoses into custom forms.

- Clamps + Jigs: For repeated or bulk installations, jigs help you maintain consistent shapes.

- Tubing Bender: Typically used for metal or hard plastics, but useful for very thick silicone hose kits.

- Heat Gun (optional): Only on low heat, and used cautiously, if approved by the hose manufacturer.

How to Bend Silicone Hoses by Hand?

If you don’t have a fancy tubing bender or a tubing jig, here’s a safe way to bend tubing by hand:

- Slide an internal bending spring that matches the tubing’s inside diameter into the tube.

- Mark the angle you want to bend the tubing using a marker or tape as a visual guide.

- Slowly flex the tubing, pushing it little by little into the shape you want. Don’t try to do it all at once.

- Hold or clamp the tubing in place for a few minutes so it retains its shape.

- Remove the spring only after the tubing is in the correct position and installed.

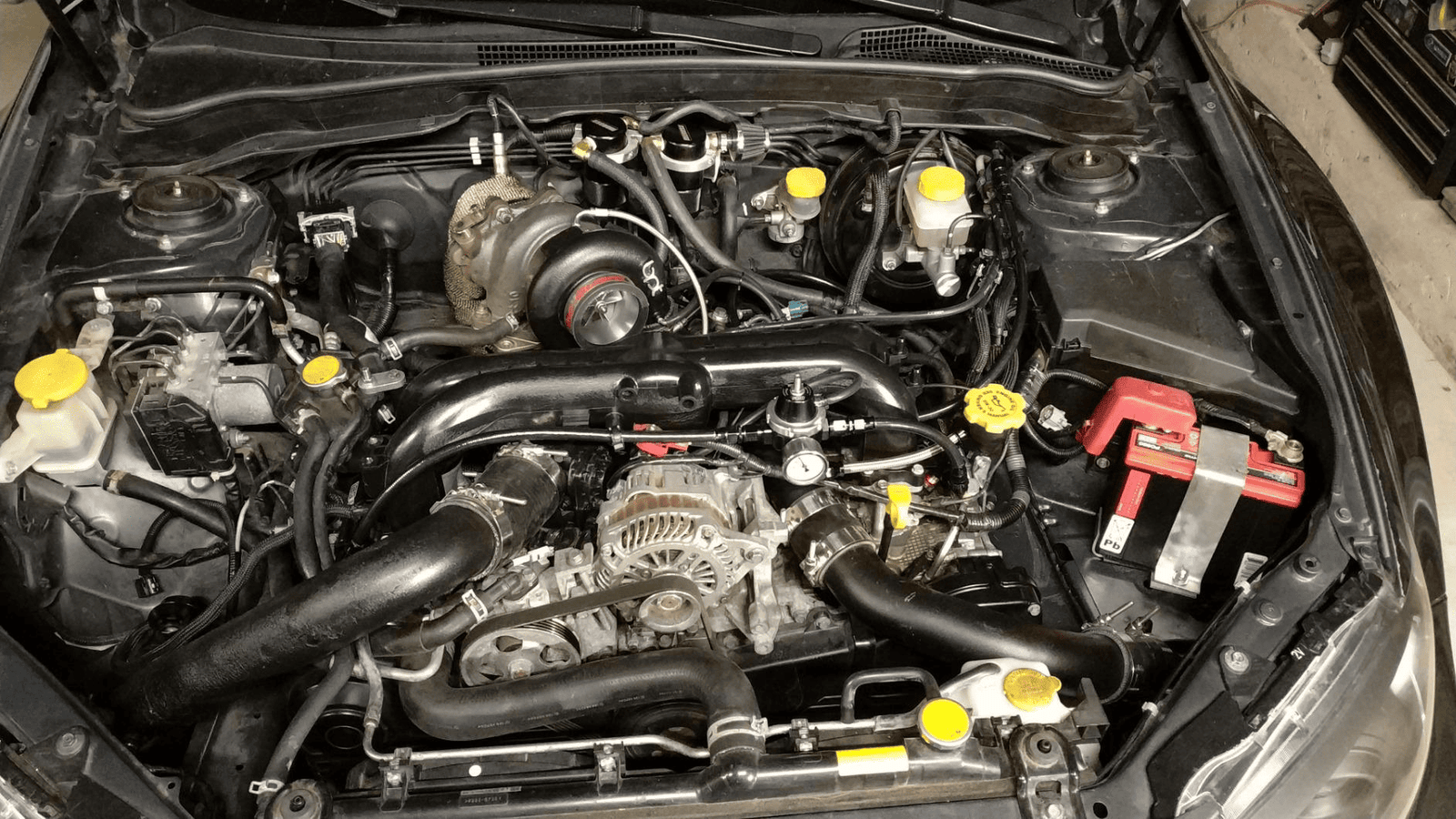

- This technique is especially useful when working in tight engine bays or bending silicone coolant hoses on custom builds.

Can You Heat Silicone to Shape It?

Yes, you can, but most pros don’t recommend it.

Heat can make silicone more pliable, but it can also damage the internal mesh reinforcement or lead to premature degradation. If you must use heat:

- Use a low-temperature heat gun

- Keep the gun moving to avoid hot spots

- Use internal support (spring or mandrel)

- Allow the hose to cool while clamped in the desired shape

But remember: do this only if your hose’s manufacturer confirms it’s safe. Some radiator hoses or heater hoses are designed for reshaping, but most aren’t.

Can Silicone Bend Without Breaking?

Yes, that’s why it’s good for cars. Silicone can handle vibration, engine heat, and a little bit of flex without cracking. That said, it’s not infinitely stretchy. If you bend it past its elastic limit or stress it at sharp angles, you can still get fatigue or rupture over time.

Always support the hose internally and avoid sharp corners or twists

Common Mistakes When Bending Silicone Hose

Here are the most common mistakes:

- Heating without internal support causes bubbles or the wall to collapse.

- Using a metal wire instead of a spring, it will puncture the wall of the hose.

- Forcing the hose into place – it will crack or have internal stress.

- Not paying attention to the bend radius, it will fail under pressure over time.

- Cutting the hose too short – it won’t have any room to move or expand.

- Take your time and always plan your bend before you cut or force the hose.