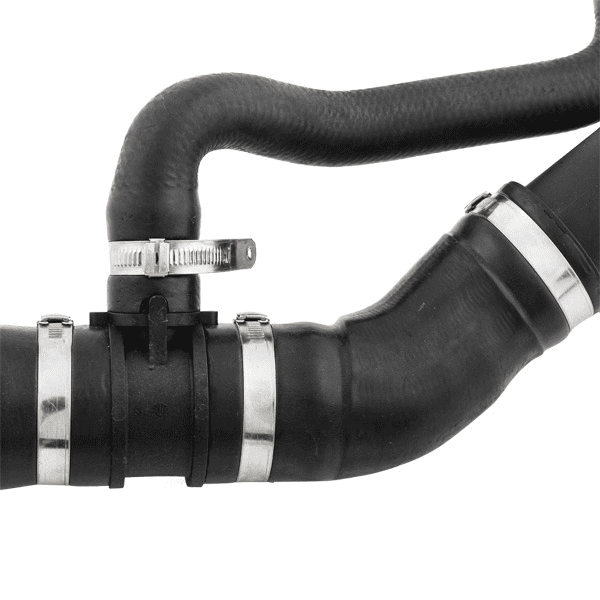

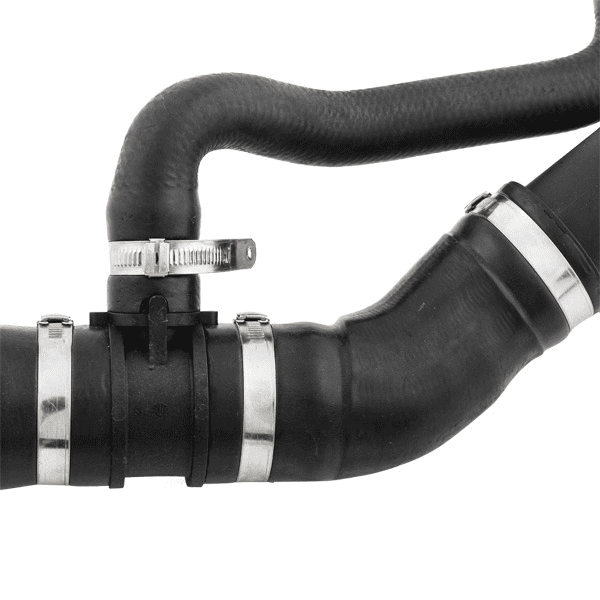

A hose clamp is used to secure hoses to pipes or connectors, primarily to prevent the hose from slipping off, which could lead to liquid or gas leaks. This article provides detailed information about hose clamps. After reading this guide, you will have a better understanding of hose clamps.

A hose clamp is a device that you use to attach and secure a hose to a fitting, When you tighten the clamp, it creates a seal so that no fluid leaks out and the hose stays connected. People use hose clamps all the time in mechanical, automotive, and plumbing applications because they hold hoses in place really well.

From heavy-duty industrial use to everyday household applications, hose clamps help keep things stable and prevent leaks.

What is a Hose Clamp?

A hose clamp, also known as a hose clip, is a device used to secure a hose to a fitting. It creates a tight seal between the hose and the connection point to prevent air or liquid leaks.

Hose clamps come in various sizes and types for different applications, including automotive, plumbing, industrial, and agricultural environments. Whether it’s preventing a radiator leak in a car or securing pipes together, hose clamps make it possible. Hose clamps are essential components for securely connecting hoses to pipes, especially when handling pressure or flow.

How Do Hose Clamps Work?

Hose clamps work by squeezing the hose material around the circumference of the hose when you tighten them. This pressure forces the hose material to squeeze tightly onto the fitting. The clamp’s pressure creates a seal that prevents fluid from leaking out through any gaps or cracks. Depending on the type and design of the clamp, you’ll use different mechanisms—such as screws, springs, or quick-release actions—to tighten and hold the clamp in place.

Here’s how clamping works:

Position the hose

You put the hose over the fitting.

Slide on the clamp

You slide the clamp over the end of the hose, covering the fitting area.

Tighten the clamp

You engage a screw, bolt, or other mechanism to tighten the clamp, which squeezes the hose tight.

What Are the Different Types of Hose Clamps?

Hose clamps come in several types, each with their own unique features and best use cases:

Worm Gear Clamps:

These are the most common. They consist of a band with a screw thread pattern cut into it. When you turn the screw, it pulls the band tighter around the hose.

Applications: Automotive engines, plumbing systems, and garden hoses.

T-Bolt Clamps:

These are heavy-duty clamps with a bolt that tightens the clamp uniformly around the hose.

Applications: High-pressure systems and industrial applications.

For a detailed introduction to Worm Gear Clamps and T-Bolt Clamps, please see this article

Spring Clamps:

These are made of spring steel. They maintain pressure as the clamp is compressed or expanded.

Applications: Fuel lines and vacuum hoses in automotive systems.

Wire Hose Clamps

This hose clamp is made of a piece of wire bent into a loop and tightened by screwing or twisting the end.

Application: Small pipes or hoses in homes or cars

Quick-Release Clamps

These clamps allow for quick installation and removal and are usually applied by hand, without the need for tools

Applications: Typically used in applications where frequent hose disconnection is required

Ear Clamps

These hose clamps have an “ear” or “lip” that is pressed onto the hose using a special crimping tool. The ear helps maintain even pressure around the hose.

Applications: Commonly found in automotive and HVAC systems

Heavy-Duty Clamps

These hose clamps are designed for industrial or high-pressure applications and are made of thicker materials such as stainless steel for durability and pressure resistance

Applications: Suitable for industrial equipment, high-pressure hoses, and other heavy-duty applications.

Pinch Clamps:

You crimp them into place with pliers. They provide a tamper-proof connection.

Applications: Low-pressure situations and sealed environments.

If you want to hose clamp, please contact us!

The Difference Between a Hose Clip and a Hose Clamp

Though people often use the terms interchangeably, there is a difference between hose clips and hose clamps. Hose clips are usually lighter, often made of a combination of metal and plastic, and have a spring mechanism to keep them tight. They’re great for lightweight connections where you need flexibility and ease of use.

Hose clamps, on the other hand, are beefier and built to handle higher pressure and heavier loads. They’re used in more demanding applications where you need to know they’re not going to let go.

Do Hose Clamps Stop Leaks?

Yes, hose clamps do a good job of stopping leaks if you use them right. They create a tight seal that keeps fluids, gases, or air from getting out. But if you don’t install them correctly—like if you tighten them too much or put them on wrong—they can damage the hose and cause leaks.

Common Mistakes to Avoid:

Tightening them too much

This can damage the hose and make it crack or tear.

Using the wrong size

If the clamp is too big or too small, it won’t seal correctly.

Putting them on the wrong

You have to put the clamp on the right to make sure it doesn’t leak.

How to Tighten a Hose Clamp Correctly

Choose the Correct Size

Make sure the clamp fits the diameter of your hose.

Put the Clamp On

Slide the clamp over the fitting on the end of the hose.

Tighten It Up

Use a screwdriver or a wrench to tighten down the clamp, slowly, until it’s snug.

Check for Leaks

Test it by putting a little bit of pressure or fluid through the hose.

Caring for Your Hose Clamp

To make your hose clamps last longer and prevent failures:

Inspect Regularly

Look for corrosion, wear, or damage.

Replace When Necessary

Swap out old clamps that don’t hold tight anymore.

Clean the Connection Point

Remove dirt and debris before you put on a clamp to get the best seal.

How to Put a Hose Clamp Back Together

When you have to put a clamp back together:

Put the Parts in Place

Make sure all the parts are where they’re supposed to be.

Put the Clamp Back Together

Put the screw or tightening thing back in it.

Put the Clamp Back on the Hose and Tighten It Up

Slide the clamp back over the hose and tighten it up.

Summary

Hose clamps are a simple and effective solution for securing hoses and preventing leaks in a variety of applications. By understanding the different types of hose clamps, how to use them correctly, and what to do to maintain them, you can get the best performance and reliability out of them.