Quality Control System

Our High Standards

Our products adhere to the strict product quality standards of ISO 9001:2015 and IATF 16949:2016.

Quality Management System

Our production site strictly implements IATF16949, ISO 9001 standards. We carry out quality control at every stage from raw materials to finished products, and are supervised by our quality inspection personnel.

Precise Specifications

From design, drawing, production, quality inspection, packaging and delivery, quality is not compromised in every step, and the diameter tolerance of the inner tube has been controlled at least +-0.1MM. 100% Factory Inspection

Customized Service

We support OEM and ODM services, and can customize according to different needs of customers, providing silicone tube solutions that meet special specifications and industry standards. Whether it is size, color, hardness, etc., we can respond flexibly

Customize Your Product

Our products have been sold all over the world, including more than 120 countries and regions in Europe, North America, South America, Asia, Australia, the Middle East, etc. Our silicone hoses have also received praise from many customers.

Testing Capabilities

At hbkinglin, we use advanced testing equipment to ensure the durability and performance of our products. Our tests include:

Low-Temperature Test

Test silicone hoses for flexibility and performance in extremely low temperatures. Ensure hoses remain functional and do not crack or become brittle in cold environments.

Tensile Testing Test

Tests the tensile strength and elongation properties of silicone materials. It measures how much pressure the material can withstand before stretching and breaking, ensuring that the silicone hose can withstand the pressures it will face in real-world applications.

Burst Pressure Test

Test the maximum pressure a silicone hose can withstand before bursting. Ensures hoses perform reliably in high-pressure environments such as automotive systems.

High temperature resistance test

Testing silicone hoses for high temperature resistance. The hoses are exposed to high temperatures to ensure they do not degrade or lose performance under harsh temperature conditions.

Hardness Tester

Measure the hardness of silicone materials to ensure they meet required specifications. The hardness of a hose affects its durability and flexibility in various applications.

Aging Test Chamber

Testing for long-term durability and resistance to aging due to environmental factors such as UV rays, ozone and humidity. Ensuring the silicone hose has a long service life without degradation.

Compression Set Testing

Measures the ability of silicone to return to its original shape after being compressed for a long period of time. Ensures the hose is flexible and resilient in applications where it is repeatedly compressed.

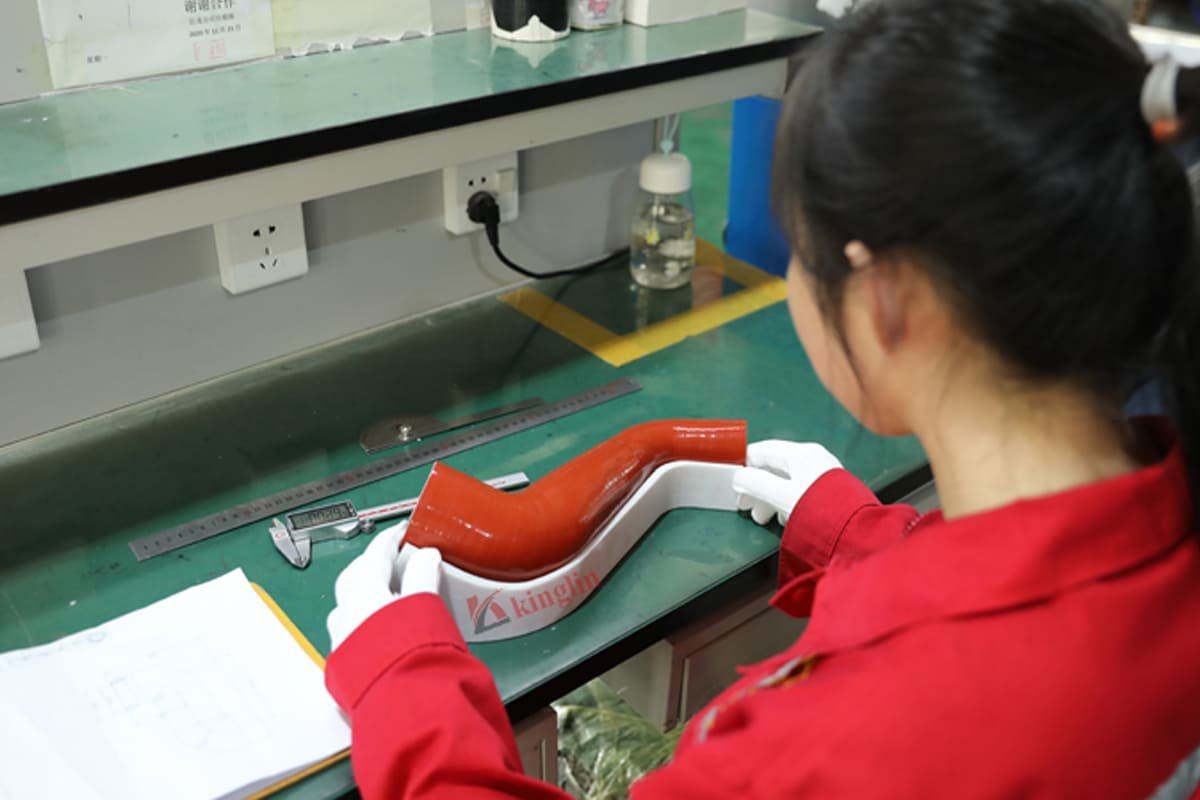

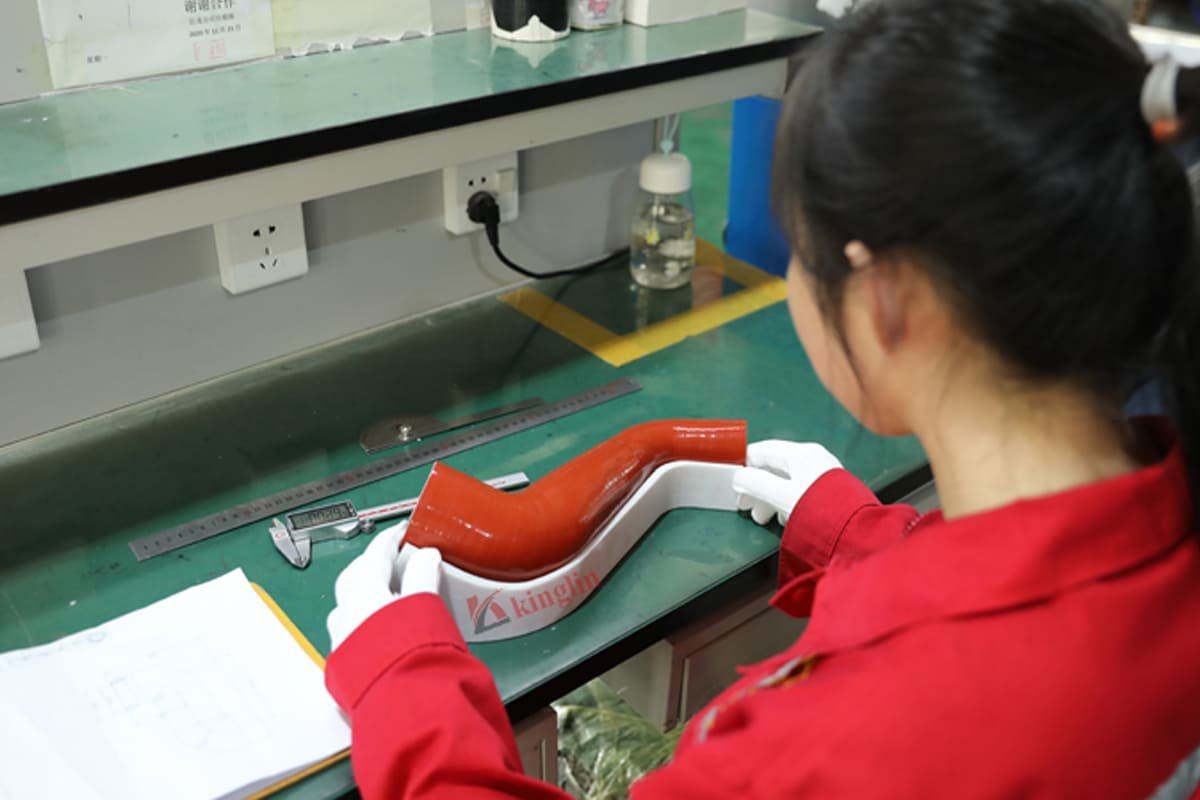

Dimensional Measurement Instruments

Accurately measure the inside and outside diameters, wall thickness, and other critical dimensions of silicone hoses. Ensure the hose meets the exact specifications your customers require.

Stringent Quality Control at Every Step

Quality control is built into every stage of our production. From raw material selection to final packaging, our production line follows a strict process to ensure that each silicone hose meets the highest standards. Our dedicated quality control team conducts spot checks and in-depth assessments throughout the process to prevent any defects.

Raw Material Inspection

Ensure that the raw silicone and any other materials used in production meet the required specifications before entering the manufacturing process.

In-Process Quality Control

Monitor production at various stages to identify and correct defects early in the manufacturing process.

Semi-Finished Product Testing

Inspect hoses after initial production stages to ensure they meet performance standards before further processing.

Final Product Testing

Ensure the final products meet all performance, safety, and customer requirements before being approved for packaging.

Packaging Inspection

Ensure the packaging process maintains product quality and prevents damage during shipping

Pre-Shipment Quality Check

Ensure that the products shipped in this batch meet the customer’s order requirements and quality standards

Our Factory Insight

Frequently Asked Questions

If you have any questions, please feel free to contact us so that we can serve you a better product or service. We also warmly welcome you to share your expertise, let’s create an open space for exchange and learning for everyone passionate about the silicone hose industry.

Email:service@hbkinglin.com

Phone:008615613933397

Contact us for a free sample

If you have any questions or request a quote, please send us a message. Our experts will get back to you within 14 hours and help you choose the right hose.