If you buy or work with hydraulic equipment, you know how confusing it can be to pick the right hydraulic hose. Choosing the wrong hose can cause leaks, safety problems, or downtime. Neste guia, you’ll learn about each hose type and how to choose the best one for your needs.

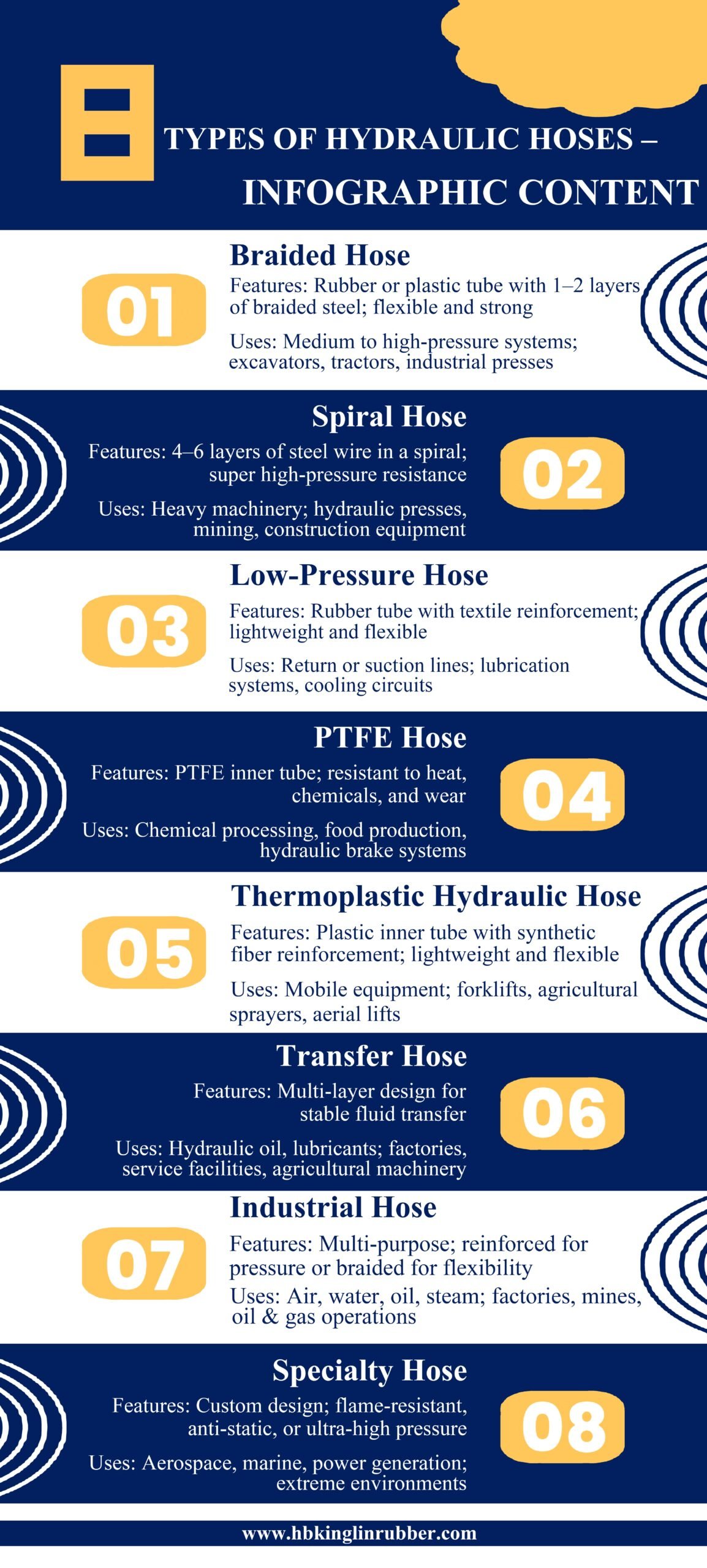

Mangueiras hidráulicas come in different types based on how they are made, what materials they use, and how much pressure they can handle. The main types are braided hoses, spiral hoses, low-pressure hoses, PTFE hoses, thermoplastic hoses, transfer hoses, industrial hoses, and specialty hoses. Each type works best in certain conditions. Quando você escolhe uma mangueira, think about temperature, produtos químicos, the environment, and safety standards like SAE, ISO, and EN.

Here’s a closer look at each type of hydraulic hose, what it’s made of, and where it’s used.

Tipos de mangueiras hidráulicas

Braided Hose

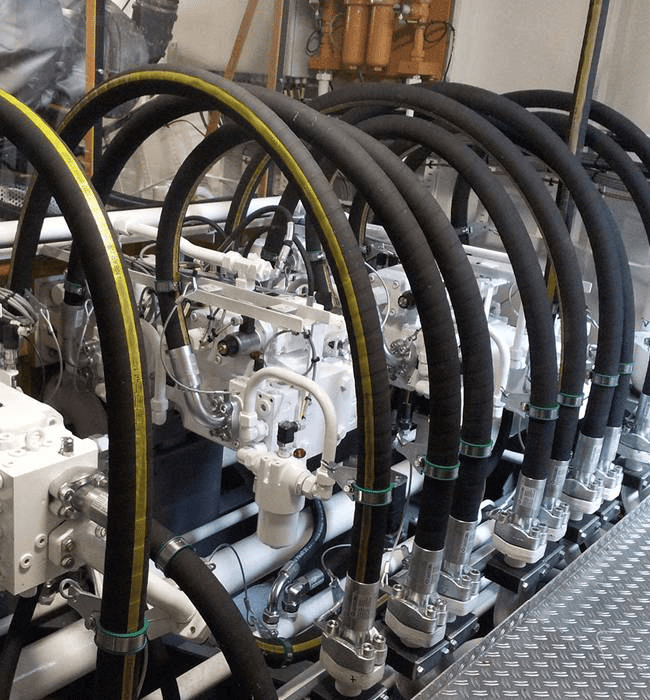

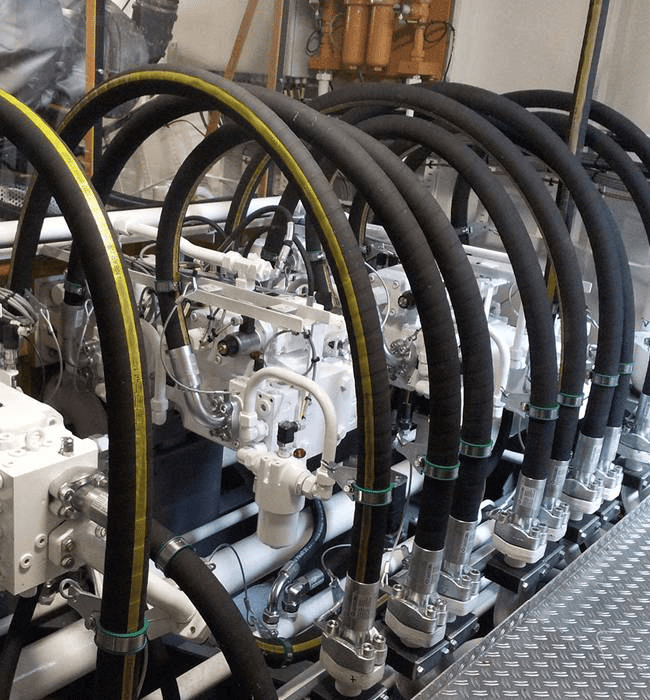

When you think of standard hydraulic hoses, you probably picture a braided hose. These are very common in machines like excavators, tratores, and industrial presses.

A braided hose has a rubber or plastic inner tube with one or two layers of braided steel wire around it. This gives it a good mix of flexibility and strength for medium- to high-pressure systems.

Hoses built to SAE 100R1, SAE 100R2, or EN 853 1SN/2SN standards are reliable in tough conditions. When you use our braided hoses, you’ll see they are easy to bend, resist kinking, and keep working smoothly under constant use.

They last a long time and maintain steady pressure and fluid flow, making them perfect for machines that need both reliability and flexibility.

Spiral Hose

If your system works under very high pressure or faces sudden pressure spikes, you’ll need spiral hoses.

These hoses have four or six layers of steel wire wound in a spiral pattern, making them very strong. Many spiral hoses follow SAE 100R12, 100R13, or EN 856 4SP/4SH standards.

When you use our spiral hoses, they last a long time and can handle repeated pressure surges without breaking.

They are perfect for heavy-duty machines like hydraulic presses, mining equipment, e máquinas de construção. You can trust them to work safely and reliably, Mesmo em condições difíceis.

Low-Pressure Hose

Not all hydraulic lines carry high pressure. Low-pressure hoses are mostly used for suction or return lines that send fluid back to the tank.

They have an oil-resistant rubber inner tube and a textile layer that keeps them light and flexible. They follow SAE 100R4 standards.

Our low-pressure hoses are easy to handle, resist wear, and bend easily for installation in tight spaces.

They work well for lubrication circuits, cooling return lines, or any system that moves fluid without high pressure. They are strong, durável, and help keep your equipment running efficiently.

PTFE Hoses

When you deal with chemicals or high temperatures, PTFE hoses (also called Teflon hoses) are the right choice.

Their inner tube is made from PTFE, which resists chemicals, calor alto, and friction. They follow SAE 100R14 standards and can work in temperatures from -70°C to +260°C.

Our PTFE hoses last a long time, keep fluids flowing smoothly, and reduce contamination. They are perfect for chemical plants, food production, and hydraulic brake systems.

You can rely on them to stay strong and safe, even in extreme conditions.

Thermoplastic Hydraulic Hose

If you need hoses that are light, flexível, and easy to handle, thermoplastic hoses are a good choice.

They are reinforced with layers of synthetic fiber instead of steel wire, and the inner tube is made of durable plastic.

They usually meet SAE 100R7 and 100R8 standards. Our thermoplastic hoses are easy to install in tight spaces, resist wear and weather, and perform reliably.

They are ideal for forklifts, agricultural sprayers, and aerial lifts. You get strong hoses without extra weight, which makes installation easier and keeps them durable for a long time.

Transfer Hoses

You use transfer hoses to move hydraulic fluids, Óleos, or other liquids inside a system.

They have a strong inner tube, layers of textile or wire reinforcement, and a protective cover. Our transfer hoses keep fluid flow steady under moderate pressure, resist damage, and handle many types of fluids safely.

They are great for oil transfer, line flushing, and other fluid-handling jobs. Using our hoses helps your operations run smoothly and efficiently.

Industrial Hoses

Industrial hoses are not just for hydraulic systems. They can carry air, água, óleo, or steam in factories, mines, or oil and gas facilities.

Some have steel wire for high pressure, and others use textile braids for flexibility.

Our industrial hoses are strong, versatile, e durável. They work well in tough conditions and handle different fluids and tasks.

They are ideal for factories, mining operations, and energy production, keeping your work safe and efficient.

Specialty Hoses

Às vezes, your projects need hoses that go beyond normal standards.

Specialty hoses are custom-made for extreme or special conditions. They may be flame-resistant, anti-static, or able to handle ultra-high pressure.

Our specialty hoses are built to meet your exact needs, giving you safety, durabilidade, and reliability. They are used in aerospace, marinho, and power plants where performance is critical.

Choosing our specialty hoses ensures that even the hardest jobs are handled safely and efficiently.

Types of Hydraulic Hose Fittings

Fittings connect hoses safely. There are straight, cotovelo, tee, and cross fittings. Quick couplers let you attach or remove hoses fast. Always match your fittings to your hose type and standard, like SAE, BSP, JIC, or ORFS, to prevent leaks.

What to Consider When Choosing a Hose

Here are some things to check:

Pressão: Choose a hose that can handle pressures exceeding your system’s maximum pressure.

Fluid: Make sure the hose material is suitable for your fluid, such as oil, water-glycol, or synthetic fluids.

Temperatura: Consider the fluid temperature and the surrounding environment.

Environment: Luz solar, produtos químicos, or abrasion can wear down the hose.

Size and Flow: Use the sizing chart to determine the appropriate diameter for your flow rate.

Standards: Check SAE, ISO, and EN standards for safety.

Reinforcement type: In hydraulic hoses, the type of reinforcement is a critical factor that determines the hose’s pressure bearing capacity, flexibilidade, e durabilidade.

If you’re unsure, Contate-nos. Com mais 20 anos de experiência, we can provide expert advice and help you select the right hydraulic hose.

Resumo

Hydraulic hoses are a vital component of hydraulic systems. Choosing the right hose ensures safe, reliable, and smooth operation. Whether braided, spiral, or low-pressure, consider pressure, temperature, and fluid compatibility to make the right choice.

Kinglin specializes in a wide variety of hydraulic hoses for various industries. We can help you find the right hydraulic hose for your application, offering consistent quality and on-time delivery. Contact us to schedule your next hydraulic hose order!