Sistema de controle de qualidade

Nossos altos padrões

Nossos produtos aderem aos rigorosos padrões de qualidade do produto ISO 9001:2015 e IATF 16949:2016.

Sistema de Gestão da Qualidade

Nosso local de produção implementa estritamente IATF16949, ISO 9001 padrões. Realizamos controle de qualidade em todas as etapas, desde matérias-primas até produtos acabados, e são supervisionados pelo nosso pessoal de inspeção de qualidade.

Especificações precisas

Do projeto, desenho, produção, Inspeção de qualidade, embalagem e entrega, a qualidade não é comprometida em todas as etapas, e a tolerância do diâmetro do tubo interno foi controlada pelo menos +-0,1MM. 100% Inspeção de Fábrica

Serviço personalizado

Apoiamos serviços OEM e ODM, e pode personalizar de acordo com as diferentes necessidades dos clientes, fornecendo soluções de tubos de silicone que atendem a especificações especiais e padrões da indústria. Quer seja tamanho, cor, dureza, etc., podemos responder com flexibilidade

Personalize seu produto

Nossos produtos foram vendidos em todo o mundo, incluindo mais de 120 países e regiões da Europa, América do Norte, Ámérica do Sul, Ásia, Austrália, o Oriente Médio, etc.. Nossas mangueiras de silicone também receberam elogios de muitos clientes.

Capacidades de teste

Aquele hbkinglin, usamos equipamentos de teste avançados para garantir a durabilidade e o desempenho de nossos produtos. Nossos testes incluem:

Teste de baixa temperatura

Teste mangueiras de silicone quanto à flexibilidade e desempenho em temperaturas extremamente baixas. Certifique-se de que as mangueiras permaneçam funcionais e não quebrem ou se tornem quebradiças em ambientes frios.

Teste de teste de tração

Testa a resistência à tração e as propriedades de alongamento de materiais de silicone. Mede quanta pressão o material pode suportar antes de esticar e quebrar, garantindo que a mangueira de silicone possa suportar as pressões que enfrentará em aplicações do mundo real.

Teste de pressão de ruptura

Teste a pressão máxima que uma mangueira de silicone pode suportar antes de estourar. Garante que as mangueiras funcionem de forma confiável em ambientes de alta pressão, como sistemas automotivos.

Teste de resistência a altas temperaturas

Testando mangueiras de silicone para resistência a altas temperaturas. As mangueiras são expostas a altas temperaturas para garantir que não se degradem ou percam desempenho sob condições adversas de temperatura.

Testador de dureza

Meça a dureza dos materiais de silicone para garantir que atendam às especificações exigidas. A dureza de uma mangueira afeta sua durabilidade e flexibilidade em diversas aplicações.

Câmara de teste de envelhecimento

Testes de durabilidade a longo prazo e resistência ao envelhecimento devido a fatores ambientais, como raios UV, ozônio e umidade. Garantir que a mangueira de silicone tenha uma longa vida útil sem degradação.

Teste de conjunto de compressão

Mede a capacidade do silicone de retornar à sua forma original após ser comprimido por um longo período de tempo. Garante que a mangueira seja flexível e resiliente em aplicações onde é comprimida repetidamente.

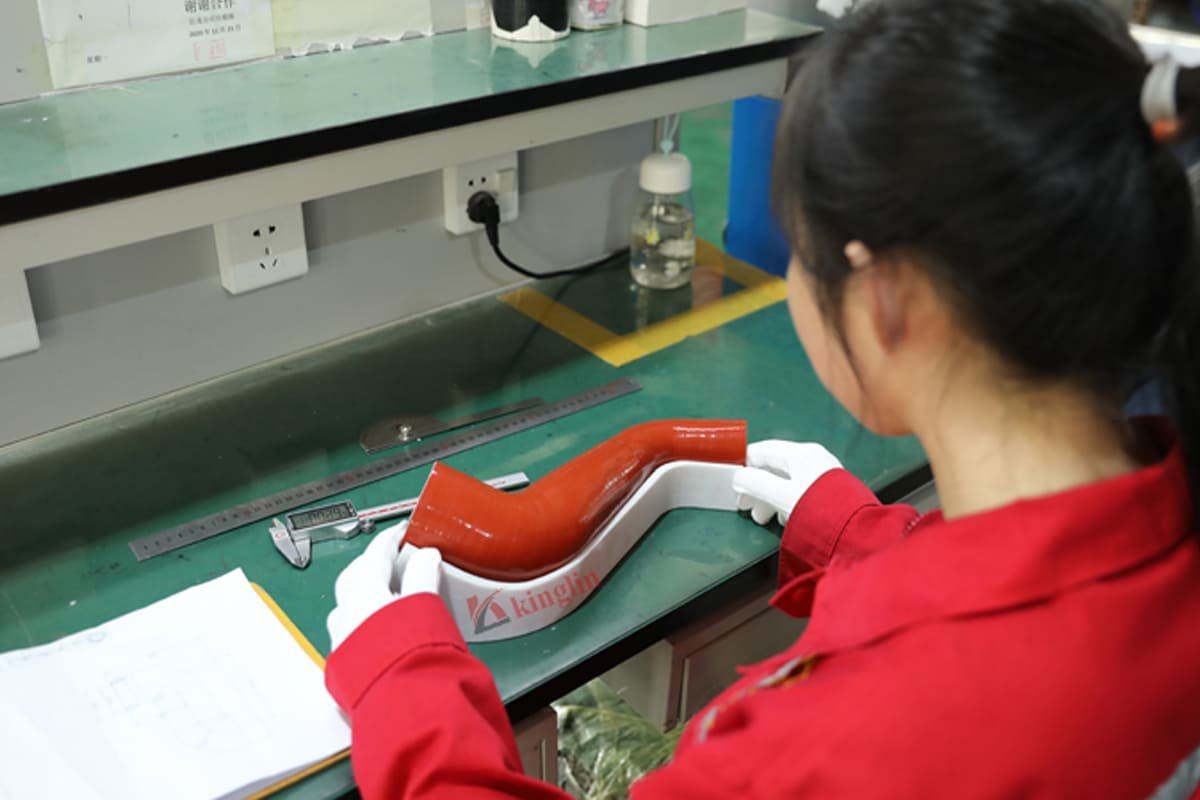

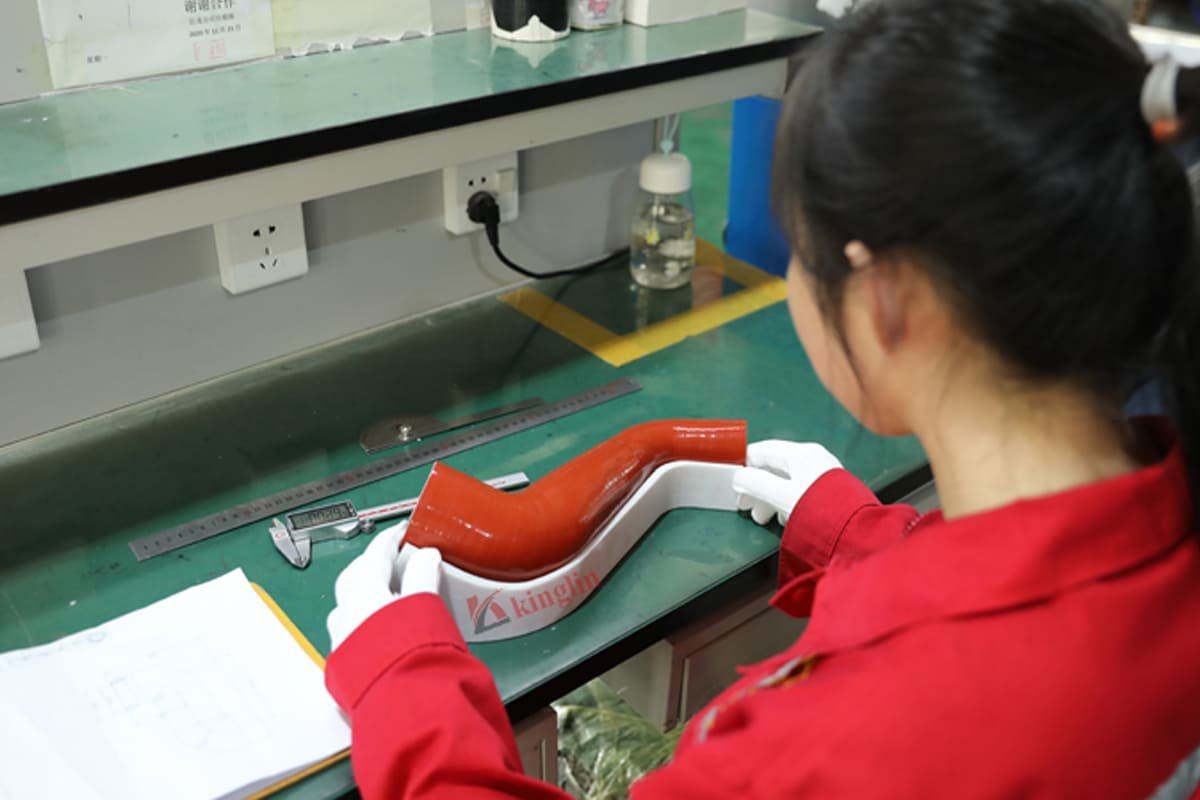

Instrumentos de medição dimensional

Accurately measure the inside and outside diameters, espessura da parede, and other critical dimensions of silicone hoses. Ensure the hose meets the exact specifications your customers require.

Stringent Quality Control at Every Step

Quality control is built into every stage of our production. From raw material selection to final packaging, our production line follows a strict process to ensure that each silicone hose meets the highest standards. Our dedicated quality control team conducts spot checks and in-depth assessments throughout the process to prevent any defects.

Raw Material Inspection

Ensure that the raw silicone and any other materials used in production meet the required specifications before entering the manufacturing process.

In-Process Quality Control

Monitore a produção em vários estágios para identificar e corrigir defeitos no início do processo de fabricação.

Teste de produto semiacabado

Inspecione as mangueiras após os estágios iniciais de produção para garantir que atendam aos padrões de desempenho antes do processamento posterior.

Teste final do produto

Garantir que os produtos finais atendam a todo o desempenho, segurança, e requisitos do cliente antes de serem aprovados para embalagem.

Inspeção de embalagens

Garantir que o processo de embalagem mantenha a qualidade do produto e evite danos durante o transporte

Verificação de qualidade pré-embarque

Garantir que os produtos enviados neste lote atendam aos requisitos do pedido e aos padrões de qualidade do cliente

Nosso insight de fábrica

Perguntas frequentes

Se você tiver alguma dúvida, Sinta -se à vontade para entrar em contato conosco para que possamos atender a você um produto ou serviço melhor. Também recebemos calorosamente você em compartilhar sua experiência, Vamos criar um espaço aberto para troca e aprendizado para todos apaixonados pela indústria da mangueira de silicone.

E-mail:Service@hbkinglin.com

Telefone:008615613933397

Entre em contato conosco para uma amostra grátis

Se você tiver alguma dúvida ou solicitar uma cotação, Por favor, envie -nos uma mensagem. Nossos especialistas voltarão para você dentro 14 horas e ajudá -lo a escolher a mangueira certa.