Silicone Hose Manufacturer

Kinglin was established in 2001, specializing in the research and development, производство, and sales of silicone hoses and rubber hoses products.

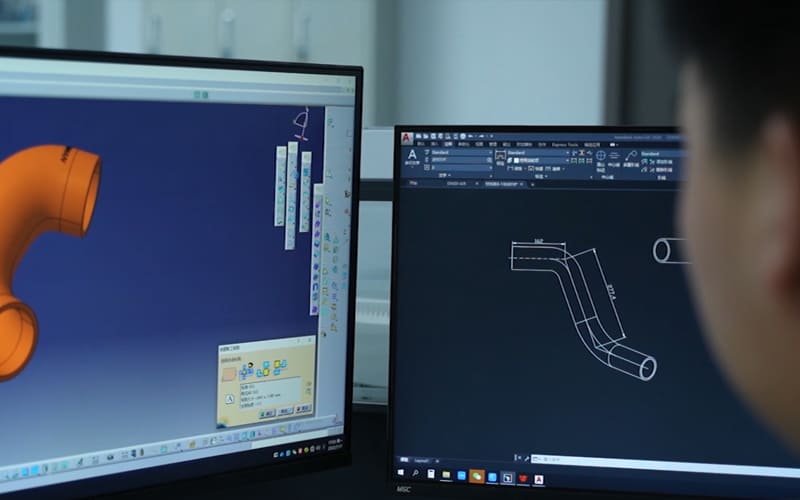

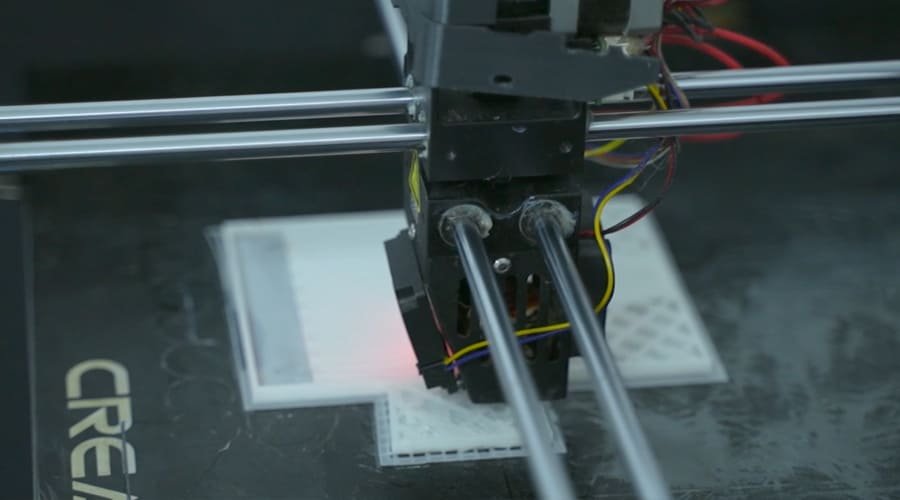

И коренно, we are committed to innovation and quality, and our silicone hose products include standard silicone hose, Силиконов маркуч за камиони, extruded silicone hose, sleeves, and custom-designed solutions to meet the stringent needs of customers worldwide.

With our expertise in silicone hose manufacturing production, you can be confident that your ideas will quickly turn into a tangible return on investment.

Contact us today, we are here to help you