Спецыяльны сіліконавы шланг

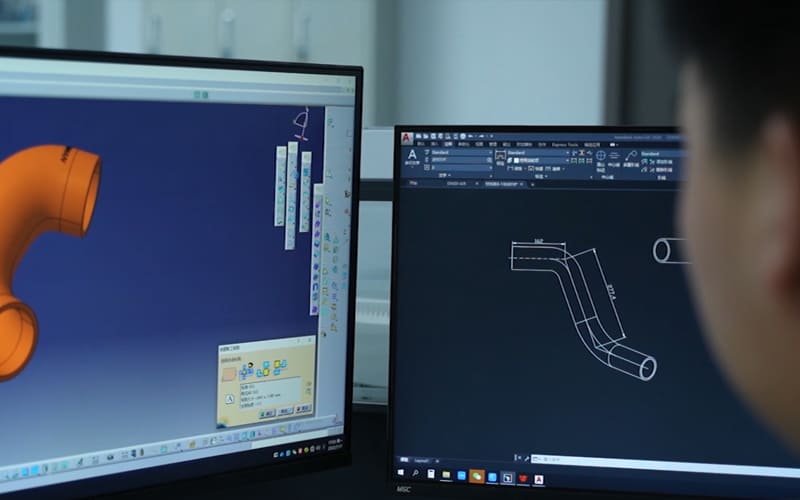

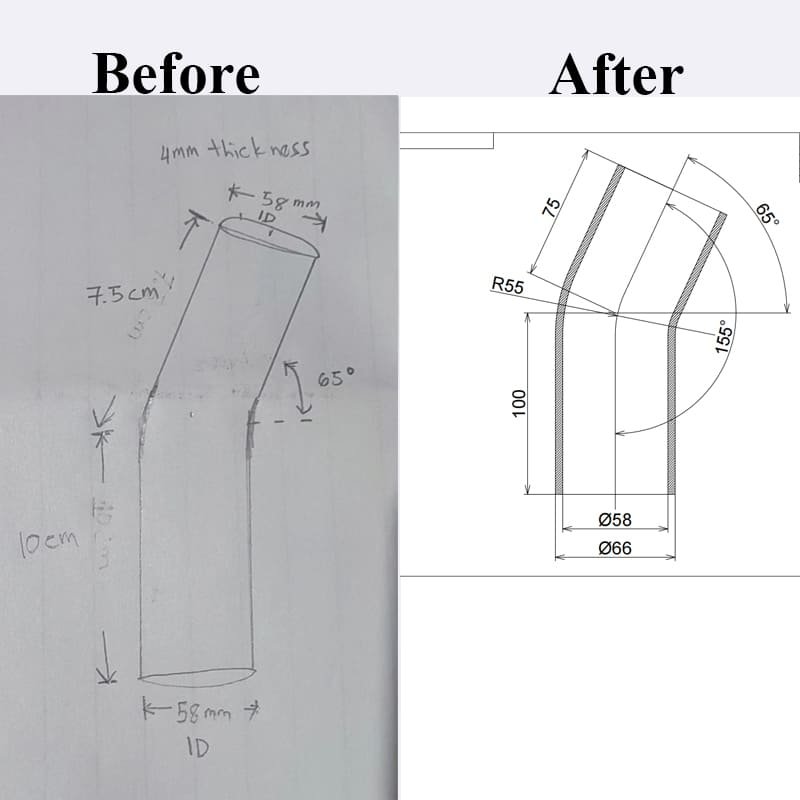

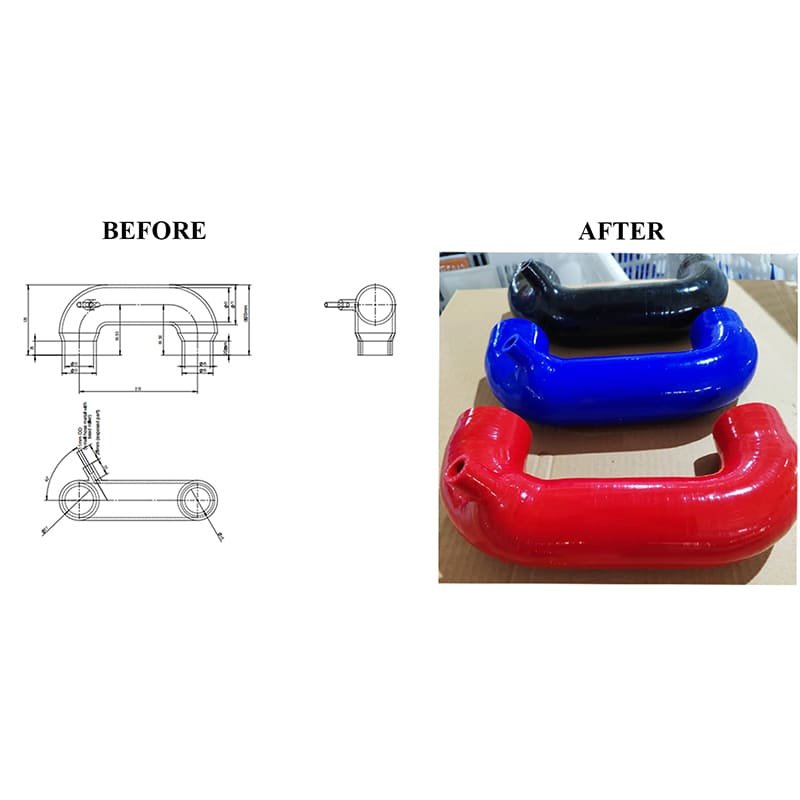

Kinglin we specialize in the design and manufacture of custom silicone hoses that meet the specific needs of your industry.

З больш 23 шматгадовы вопыт, our factory is well-equipped with the latest technology and a skilled team ready to deliver products that exceed the highest standards of quality and performance.

We specialize in standard silicone hoses, extruded silicone hoses, truck silicone hoses, silicone hose kits, heater silicone hoses, silicone intake hoses,і г.д..

Whether you need small batches or large-scale production, our flexible manufacturing capabilities ensure precision in every product. From automotive to agriculture, our hoses offer superior durability and performance under extreme conditions.

Choose Kinglin for your silicone hose needs and experience the difference that custom quality makes.