خرطوم السيليكون المخصص

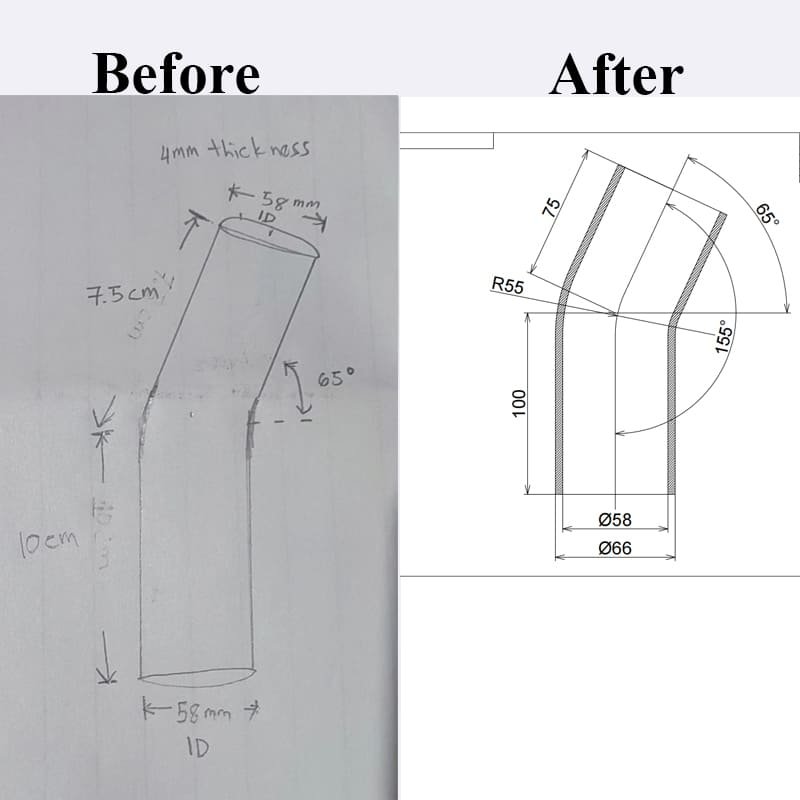

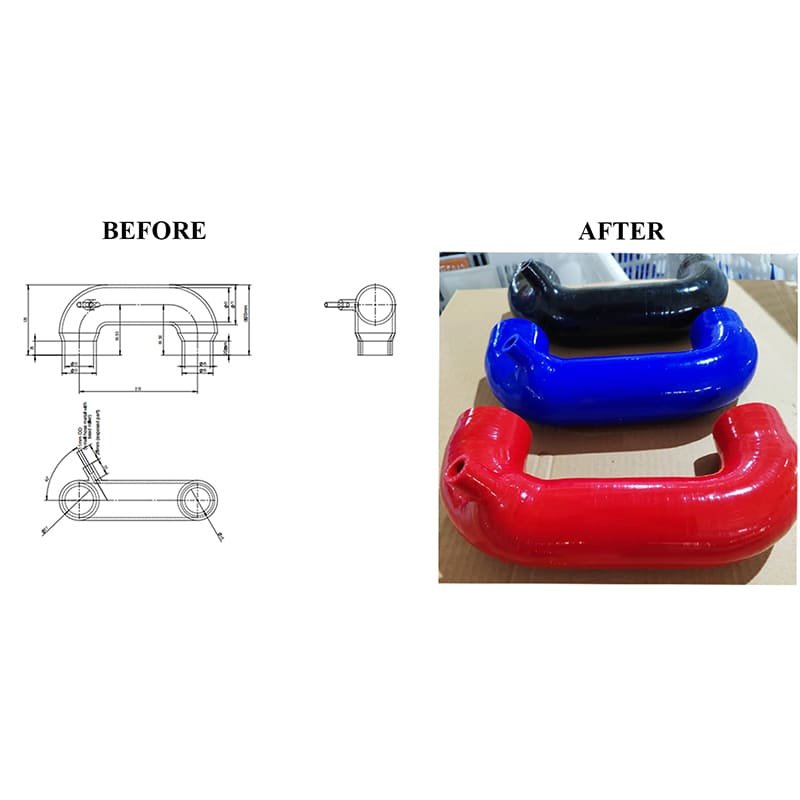

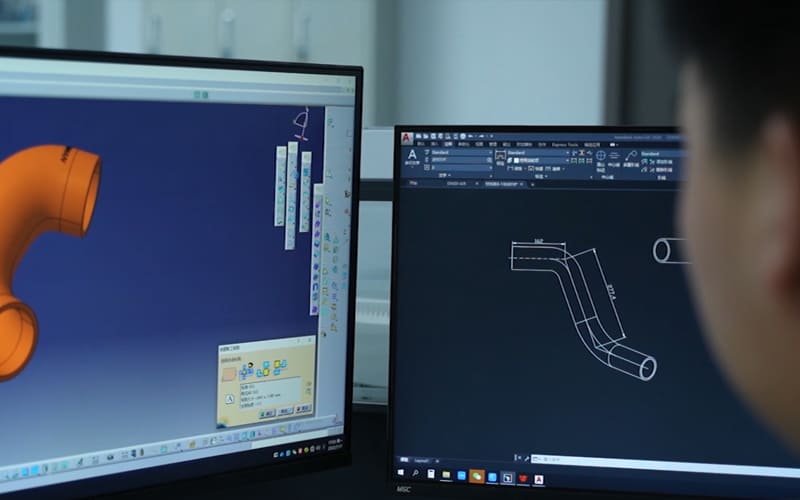

Kinglin specializes in designing and manufacturing custom silicone hoses to meet the specific needs of your industry.

مع أكثر 23 سنوات من الخبرة, our factory is equipped with advanced production equipment and an experienced technical team to provide high-quality, high-performance products.

We specialize in standard silicone hoses, خراطيم السيليكون المقذوف, خراطيم سيليكون شاحنة, silicone radiator hose kits, heater silicone hoses, silicone air intake hoses, وأكثر.

Whether you require small batches or large-scale production, we have the capacity to meet your requirements and ensure the quality of each product meets your requirements.