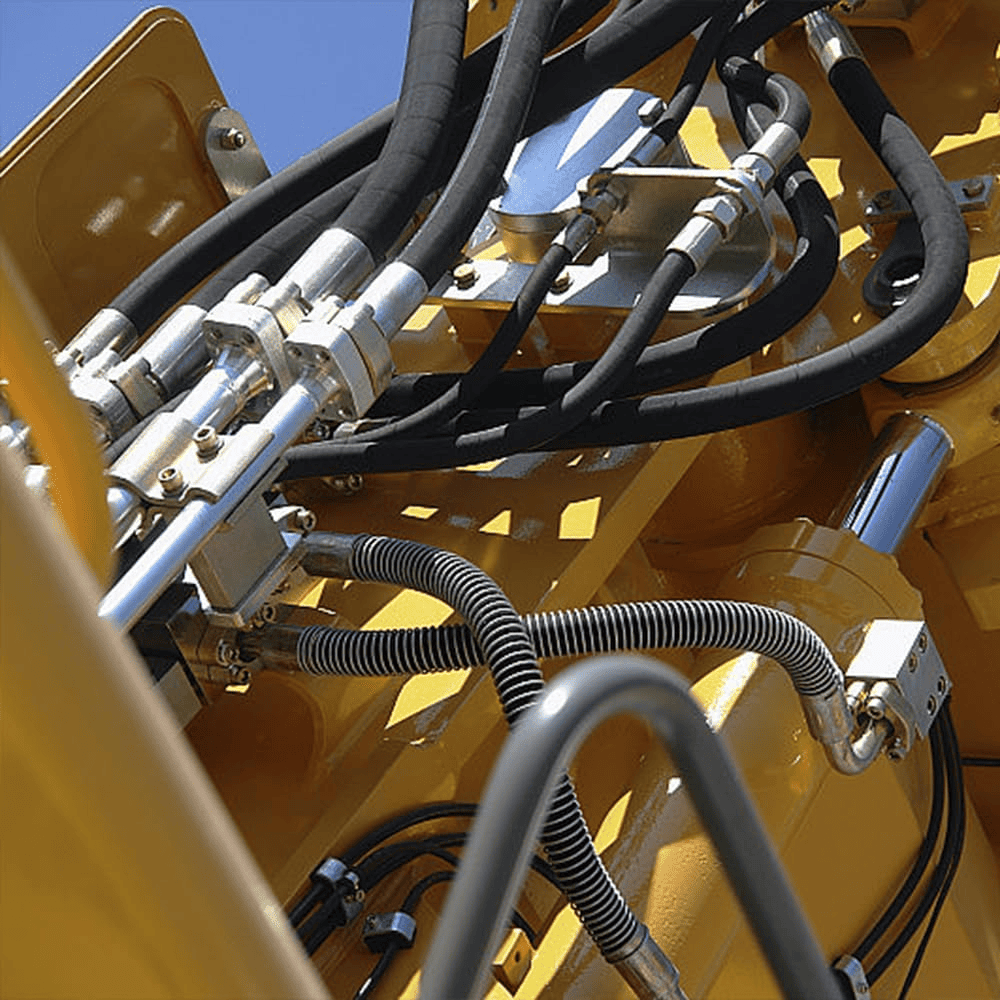

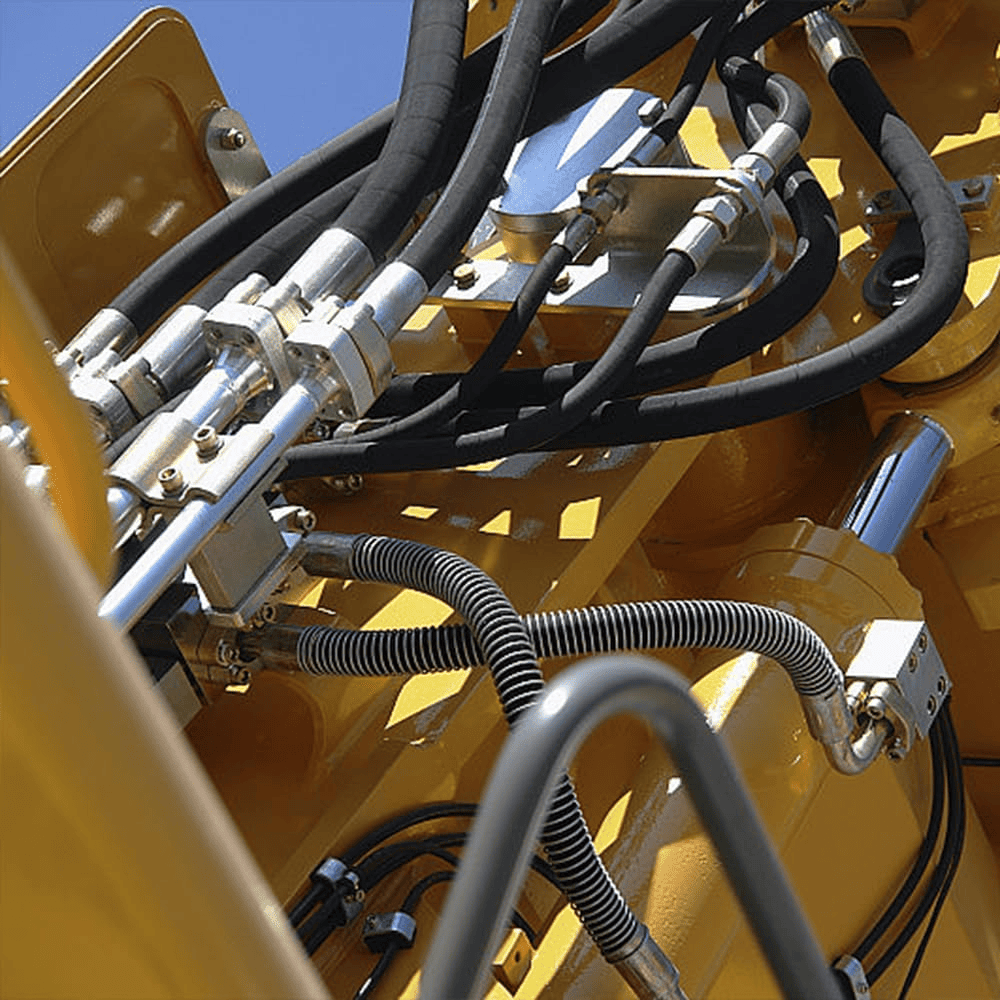

ท่อไฮดรอลิกใช้กันอย่างแพร่หลายในระบบไฮดรอลิกในเครื่องจักรก่อสร้าง, อุปกรณ์อุตสาหกรรม, เรือ, และรถยนต์. เป็นส่วนประกอบสำคัญในระบบไฮดรอลิก, ให้ความต้านทานแรงดันสูง, ทนน้ำมัน, สึกหรอ, ความต้านทานต่อวัย, และความยืดหยุ่นที่ดีเยี่ยม.

ท่อไฮดรอลิกอาจระเบิดหรือเริ่มรั่วได้จากหลายสาเหตุ, อาจทำให้งานของคุณหยุดชะงักได้.

ในบทความนี้, คุณจะได้เรียนรู้วิธีการซ่อมแซมท่อไฮดรอลิก, ที่อยู่รั่วไหล, และป้องกันความเสียหายในอนาคต.

อะไรคือ 5 ขั้นตอนในการซ่อมท่อไฮโดรลิค?

มาดูกระบวนการทีละขั้นตอนเพื่อให้คุณรู้ว่าต้องทำอะไรในภาคสนามหรือในเวิร์กช็อปของคุณ.

ขั้นตอน 1: ค้นหาความเสียหายและความดันการปลดปล่อย

ก่อนจะทำอะไรก็ตาม, ตรวจสอบให้แน่ใจว่าปิดเครื่องแล้วและปล่อยแรงดันทั้งหมดออกจากระบบ. น้ำมันไฮดรอลิกภายใต้แรงดันอาจเป็นอันตรายได้.

มองหาจุดเปียก, รอยแตก, หรือนูนบนท่อ. เมื่อคุณพบพื้นที่ที่ไม่ดีแล้ว, ทำเครื่องหมายไว้เพื่อให้คุณรู้ว่าต้องทำงานที่ไหน.

เคล็ดลับความปลอดภัย: อย่าใช้มือคลำหารอยรั่ว. ของเหลวแรงดันสูงสามารถเจาะผิวหนังของคุณได้. ใช้กระดาษแข็งหรือกระดาษแทน.

ขั้นตอน 2: เลือกท่อที่เหมาะสม

คุณจะต้องมีสายยางที่ตรงกับขนาดและแรงดันของสายยางเก่า. ตรวจสอบข้อความที่ด้านข้างของท่อเพื่อดูหมายเลขชิ้นส่วน.

หากคุณไม่แน่ใจว่าจะซื้ออะไร, ติดต่อผู้จำหน่ายสายไฮดรอลิกซึ่งสามารถช่วยคุณค้นหาสายยางที่เหมาะสมได้.

ขั้นตอน 3: ตัดและจีบท่อ

ใช้คัตเตอร์ตัดท่อหรือเลื่อยละเอียดเพื่อทำเป็นเส้นตรง, ตัดสะอาด. หลีกเลี่ยงการใช้เลื่อยเลือยตัดโลหะ เพราะอาจทิ้งฝุ่นโลหะที่อาจเข้าไปในท่อได้.

ดันข้อต่อเข้าที่ปลายท่อแล้วใช้เครื่องมือย้ำสายไฮดรอลิกเพื่อยึดให้แน่น.

เคล็ดลับ: ชุดซ่อมสายไฮดรอลิกช่วยให้คุณประหยัดเวลาได้มาก. มันมักจะรวมถึงอุปกรณ์, หนีบ, และเครื่องมือจีบ.

ขั้นตอน 4: ปิดผนึกฟิตติ้ง

ตรวจสอบให้แน่ใจว่าการเชื่อมต่อของคุณได้รับการปิดผนึกอย่างดีเพื่อไม่ให้รั่วไหล.

- ใช้เทปเทฟลอนกับเกลียว NPT เท่านั้น.

- อย่าใช้น้ำยาซีลใดๆ กับข้อต่อที่มีโอริงหรือแฟลร์ 37°.

- เช็ดข้อต่อให้สะอาดก่อนขันให้แน่น.

การปิดผนึกที่ดีช่วยให้ระบบของคุณแข็งแรงและไม่รั่วซึม.

ขั้นตอน 5: ตรวจสอบการรั่วไหล

หลังจากที่คุณเชื่อมต่อท่อใหม่แล้ว, ค่อย ๆ เปิดระบบอีกครั้ง. เฝ้าระวังหยดอย่างใกล้ชิด, ฟองอากาศ, หรือเสียงแปลกๆ.

หากพบเห็นรอยรั่วเล็กๆ, ขันข้อต่อให้แน่นขึ้นอีกเล็กน้อย แต่อย่าขันให้แน่นจนเกินไป.

เมื่อทุกอย่างดูแห้งและเรียบเนียน, การซ่อมแซมของคุณเสร็จสิ้นแล้ว!

วิธีแก้ไขการรั่วไหลของไฮดรอลิกชั่วคราว

หากคุณอยู่นอกสถานที่และต้องการการแก้ไขอย่างรวดเร็ว, คุณสามารถปะท่อได้ชั่วคราว.

ทำความสะอาดบริเวณรอบจุดรั่วซึม, จากนั้นพันให้แน่นด้วยเทปซ่อมสายไฮดรอลิกหรือแผ่นกาวสำหรับท่อแรงดันสูง.

การแก้ไขด่วนนี้ควรใช้เวลานานพอที่จะทำงานให้เสร็จหรือไปที่ร้านซ่อม.

จดจำ: แพทช์เป็นเพียงชั่วคราวเท่านั้น. เปลี่ยนท่อโดยเร็วที่สุด.

วิธีการปิดผนึกท่อไฮดรอลิกอย่างถูกวิธี

การปิดผนึกที่ดีเป็นกุญแจสำคัญในการหยุดการรั่วไหล.

- ใช้เทปเทฟลอนหรือล็อคไทท์เท่านั้น 5452 บนเธรด NPT หรือ JIC.

- อย่าใช้น้ำยาซีลกับโอริงหรือข้อต่อแฟลร์.

- ทำความสะอาดทั้งสองด้านก่อนเชื่อมต่อเสมอ.

ทำความสะอาด, การเชื่อมต่อแบบแห้งจะทำงานได้ดีที่สุดและใช้งานได้นานกว่า.

คุณต้องใช้เครื่องมืออะไรในการซ่อมท่อไฮดรอลิก?

นี่คือสิ่งที่คุณควรเตรียมให้พร้อมก่อนเริ่มต้น:

- เครื่องตัดท่อหรือเลื่อยขนาดเล็ก

- เครื่องมือย้ำสายไฮดรอลิก

- ท่อและข้อต่อทดแทน

- เทปวัดหรือไม้บรรทัด

- ผ้าทำความสะอาดและน้ำยาซีล

- แคลมป์ซ่อมท่อไฮดรอลิก (เพื่อการแก้ไขที่รวดเร็ว)

การมีเครื่องมือเหล่านี้พร้อมจะทำให้การซ่อมทำได้เร็วและง่ายขึ้น.

อะไรคือสาเหตุทั่วไปของความล้มเหลวของท่อไฮดรอลิก?

หากคุณรู้ว่าทำไมท่อจึงล้มเหลว, คุณสามารถหยุดไม่ให้เกิดขึ้นอีกได้.

- การถูหรือการเสียดสี: ท่อสึกหรอจากการสัมผัสโลหะหรือท่ออื่นๆ.

- การติดตั้งไม่ถูกต้อง: ท่อที่บิดหรือโค้งงอแน่นเกินไปอาจเสียหายได้.

- ความร้อนมากเกินไป: อุณหภูมิสูงทำให้วัสดุท่ออ่อนลง.

- ของเหลวสกปรก: สิ่งสกปรกหรือน้ำในระบบทำให้ภายในท่อเสียหาย.

- กดดันมากเกินไป: การเกินพิกัดแรงดันของสายยางอาจทำให้ท่อระเบิดได้.

การตรวจสอบเป็นประจำจะช่วยให้คุณพบปัญหาเหล่านี้ได้ตั้งแต่เนิ่นๆ ก่อนที่จะทำให้เกิดการรั่วไหล.

วิธีดูแลรักษาท่อไฮดรอลิกเพื่อป้องกันการรั่วในอนาคต

การดูแลท่อช่วยให้มีอายุการใช้งานยาวนานขึ้น. นี่คือวิธีการ:

- ตรวจสอบท่อบ่อยๆ เพื่อหารอยแตกร้าว, การรั่วไหล, หรือจุดอ่อน.

- รักษาความสะอาดเพื่อให้คุณมองเห็นปัญหาได้เร็ว.

- เปลี่ยนอุปกรณ์เก่าหรือชำรุดทันที.

- ใช้ปลอกป้องกันหรือที่หนีบเพื่อหยุดการเสียดสี.

- อย่าปล่อยให้ระบบของคุณร้อนเกินไปหรืออยู่ภายใต้ความกดดันมากเกินไป.

การตรวจสอบเล็กๆ น้อยๆ เหล่านี้สามารถช่วยคุณประหยัดเวลาได้, เงิน, และความหงุดหงิดในภายหลัง.

การดูแลและบำรุงรักษาท่อไฮดรอลิกอย่างเหมาะสมสามารถยืดอายุการใช้งานของท่อได้, ปรับปรุงประสิทธิภาพของอุปกรณ์, และลดความเสี่ยงจากการทำงานผิดพลาด.

นั่นฮับคิงลิน, we are a dedicated manufacturer of hydraulic hoses. เราผลิตท่อไฮดรอลิกและอุปกรณ์เสริมคุณภาพสูง, และมีช่างมืออาชีพของเราพร้อมช่วยเหลือคุณในการเลือกสิ่งที่ถูกต้อง, ท่อคุณภาพสูง. คุณไม่จำเป็นต้องกังวลเกี่ยวกับความเสียหายของท่อภายในอายุการใช้งานปกติ. หากคุณมีคำถามใด ๆ, โปรดติดต่อเราโดยตรงและเราจะให้ทางออกที่น่าพอใจ.

สรุป

ท่อไฮดรอลิกเสียหายเป็นเรื่องปกติ. การตรวจสอบระบบท่อไฮดรอลิกของคุณเป็นประจำถือเป็นสิ่งสำคัญ. หากเกิดปัญหาใดๆ, ซ่อมแซมหรือเปลี่ยนใหม่ทันทีเพื่อให้มั่นใจว่าการทำงานมีเสถียรภาพ.