When you’re picking hoses for machines or vehicles, you’ll probably see two popular types — nylon braided hoses and stainless steel braided hoses. În acest articol, I’ll explain their features, differences, applications, and how to choose the hose that best suits your needs.

Nylon braided hoses are light, flexibil, and cheaper, which makes them great for air or fuel systems that don’t need super high pressure.

Stainless steel braided hoses, pe de altă parte, are stronger and can handle more heat and pressure. They’re used for tough jobs that need extra protection and safety.

What Is a Nylon Hose?

Nylon braided hose is a soft, flexible hose made of nylon. It is commonly used in automobiles, machinery, and other applications requiring flexible, rust-resistant hoses for conveying air, water, ulei, or chemical media.

Because nylon is light and smooth, it’s perfect for places where space is tight and you want a clean, easy fit.

How a Nylon Hose Is Built

Most nylon braided hoses have three layers:

- Inner tube – carries fuel, ulei, or air.

- Middle layer – a nylon braid that gives the hose strength.

- Outer layer – protects the hose from scratches and sunlight.

Together, these layers make the hose flexible but still strong enough for everyday use.

Advantages of Nylon braided hose

Nylon braided hose is a lightweight and flexible hose that bends easily, is easy to install, and performs well in confined spaces. Despite its light weight, it’s strong enough to handle medium-pressure systems, making it ideal for air, combustibil, and hydraulic return lines.

It’s also durable. The nylon braid protects the hose from abrasion, friction, and vibration, making it resistant to damage. It’s also resistant to corrosion and most chemicals, and won’t rust or become brittle even when exposed to oil, combustibil, or water.

Nylon braided hose can operate in high and low temperatures ranging from -40°C to +120°C and costs significantly less than stainless steel hose. If you’re looking for an affordable, flexibil, and durable hose suitable for everyday use, nylon braided hose is the best choice.

Disadvantages of Nylon Hoses

Nylon hoses have some limits:

- They can melt or weaken if they get too hot.

- They can’t handle very high pressure.

- Some chemicals might cause them to swell over time.

Aşa, if your equipment gets really hot or works under heavy pressure, nylon hoses might not last as long.

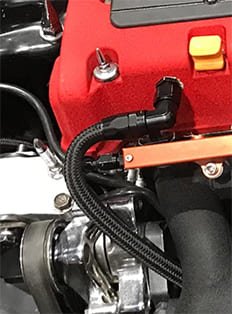

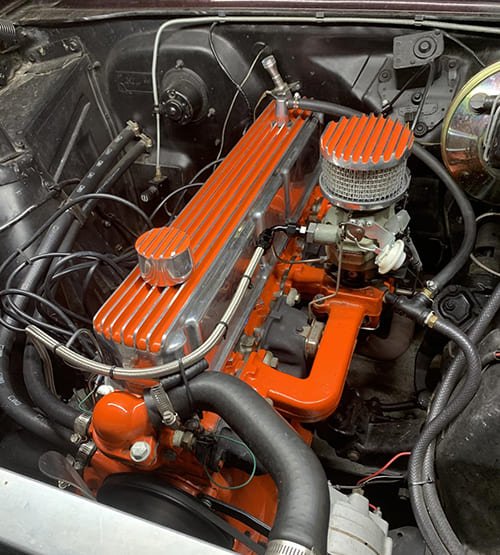

Where Nylon Hoses Are Used

You’ll often see nylon braided hoses in:

- Fuel and oil lines in cars

- Air compressors

- Machines with air or fluid systems

- Cooling and water systems

They’re best for light or medium jobs where flexibility and cost matter more than high pressure.

What is a stainless steel braided hose?

A stainless steel braided hose is a flexible tube with an outer layer made of woven stainless steel wire and an inner layer typically made of rubber or polytetrafluoroethylene (PTFE). It is used to transport liquids or gases.

The outer stainless steel braid provides reinforcement and protection, ensuring the hose maintains excellent pressure resistance and flexibility under high-pressure and high-temperature environments, preventing expansion or rupture.

It is widely used in applications such as domestic water supply systems, Echipamente industriale, Automobile, chemical engineering, and steam pipelines. It offers advantages such as corrosion resistance, high-temperature resistance, vibration resistance, and a long service life.

How a Stainless Steel Hose Is Built

Like nylon hoses, stainless steel ones also have layers:

- Inner tube – carries the fluid or gas safely.

- Steel braid – gives it strength and keeps it from bursting.

- Protective cover – sometimes added to stop scratches or corrosion.

This design makes stainless steel hoses super tough and long-lasting.

Advantages of Stainless Steel Hoses

Stainless steel braided hose is durable, safe, and reliable. If you need a hose that can withstand high pressures and harsh environments, then stainless steel braided hose is the ideal choice. The stainless steel braiding on the hose’s outer layer makes it exceptionally strong and helps protect it from being crushed, cut, or damaged.

Another major advantage is its excellent temperature resistance. It can be used in both hot and cold environments, ranging from approximately -200°C to +600°C, depending on the internal temperature of the hose. It is also rust- and corrosion-resistant, and will not wear out quickly even when used in environments with water, steam, or chemicals. Stainless steel braided hose is commonly used in hydraulic systems, chemical lines, and steam applications.

If you need a reliable product that will not fail under extreme conditions, then stainless steel braided hose is the perfect choice.

Disadvantages of Stainless Steel Hoses

Even though they’re strong, stainless steel hoses have a few drawbacks:

- They’re less flexible and harder to install in tight spaces.

- Costă mai mult.

- They can rust a little if not cared for properly.

Acestea fiind spuse, with good maintenance, they can last a really long time.

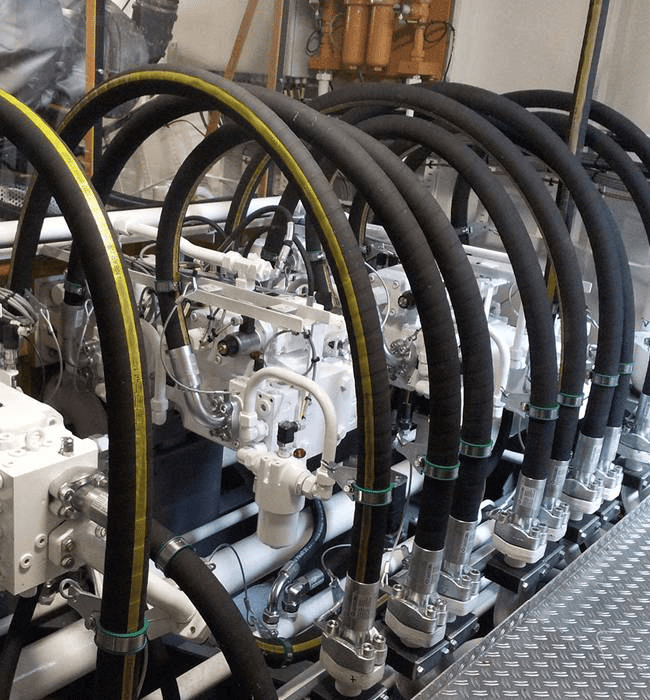

Where Stainless Steel Hoses Are Used

You’ll see stainless steel braided hoses in:

- Hydraulic systems in large machines

- Chemical and gas lines in factories

- Turbo and brake lines in race cars

- Steam and high-heat equipment

They’re made for tough environments where other hoses would break down.

How to choose nylon or stainless steel hose

It depends on your needs. If you want an inexpensive, ușor, and flexible hose, choose nylon.

If you need a strong, safe, and high-pressure-resistant material, choose stainless steel.

The choice between nylon braided hose and stainless steel braided hose depends primarily on your application environment and needs.

Nylon braided hose is suitable for low- to medium-pressure systems. It offers advantages such as light weight, flexibilitate, and easy installation. It operates in temperatures ranging from -40°C to +120°C and is commonly used in pneumatic systems and fuel lines.

Stainless steel braided hose is more suitable for high-pressure and high-temperature environments. Its outer metal braiding provides greater strength and protection, resisting mechanical damage and high-temperature corrosion. It is commonly used in hydraulic systems, steam lines, chemical transport, and automotive turbocharger systems.

Overall, if you need a lightweight, flexibil, and low-cost hose, choose nylon braided hose. If the application environment requires more demanding pressure resistance and safety, choose stainless steel braided hose.

Differences between Nylon Tubing and Stainless Steel Hose

Rating de presiune

- Nylon braided hose: Best suited for low- to medium-pressure systems, typically below 300 Psi.

- Stainless steel hose: Designed specifically for high-pressure applications, typically exceeding 1000 Psi, making it ideal for hydraulic and industrial systems.

Interval de temperatură

- Nylon braided hose: Performs well in temperatures between -40°C and +120°C, but prolonged exposure to high temperatures can degrade its performance.

- Stainless steel hose: Can withstand extreme temperatures from -200°C to +600°C, depending on the inner layer material (PTFE or rubber).

Flexibilitate

- Nylon braided hose: Excellent flexibility and easy to install.

- Stainless steel hose: Due to the metal braid, it is less flexible and requires a wider bend angle for installation.

Weight

- Nylon braided hose: Lightweight and easy to move or install.

- Stainless steel hose: Heavier due to the steel braid, but more stable and provides better protection.

Corrosion Resistance

- Nylon braided hose: Excellent resistance to water and most chemicals, and will not rust.

- Stainless steel hose: Good corrosion resistance, but prolonged exposure to salt, acid, or harsh chemicals may cause surface rust.

Cost

- Nylon braided hose: Mai accesibil, suitable for low-cost or bulk purchases.

- Stainless steel hose: More expensive, but offers a longer service life, making it a good value for critical or high-pressure systems.

Aplicații

- Nylon braided hose: Commonly used in air lines, fuel lines, and low-pressure hydraulic systems.

- Stainless steel hose: Used in hydraulic systems, chemical transfer, turbocharging lines, and steam systems where safety and performance are paramount.

Concluzie

The ultimate choice between braided nylon hose and stainless steel hose depends on your specific application needs.

If you’re still unsure whether to choose stainless steel braided hose or nylon hose, please contact our hose experts. If you’re looking for wholesale of either hose type, consider hbkinglin. We offer quality products and professional service, factory-direct wholesale pricing, and guaranteed on-time delivery. Contact us today for preferential pricing and a product catalog.

RFQ

Is stainless steel braided hose resistant to chemical corrosion?

Da, stainless steel braided hose has excellent chemical resistance and can withstand long-term use in a variety of chemical environments without rusting or damaging.

Which hose is more affordable?

Nylon braided hoses are more economical, and if cost is your primary consideration, nylon may be a better choice.

Which hose type is better for high-pressure applications?

Stainless steel braided hose is better suited for high-pressure applications because it can withstand much higher working pressures than nylon hose.