Hydraulic hoses are frequently used in tractors, camioane, and factory machinery. Have you ever wondered how they are made? Let’s break it down step by step in a simple way.

Hydraulic hoses are made by layering rubber with strong wire or fabric inside. The layers are heated and pressed together to make them strong and flexible. After that, the hoses are cut to size and fitted with metal ends using a crimping machine. in sfarsit, each hose is tested under pressure to make sure it’s safe and meets official standards.

What Do I Need to Make Hydraulic Hoses?

First, you need the right tools and materials. Here’s a list: furtun de cauciuc, fitinguri pentru furtunuri, lubricant, a ruler or calipers, a marker, safety goggles, and a hydraulic hose crimper.

A clean, safe workspace is also important. Always wear gloves and goggles when cutting or crimping hoses — the pressure and sharp edges can be dangerous.

The Basic Structure of a Hydraulic Hose

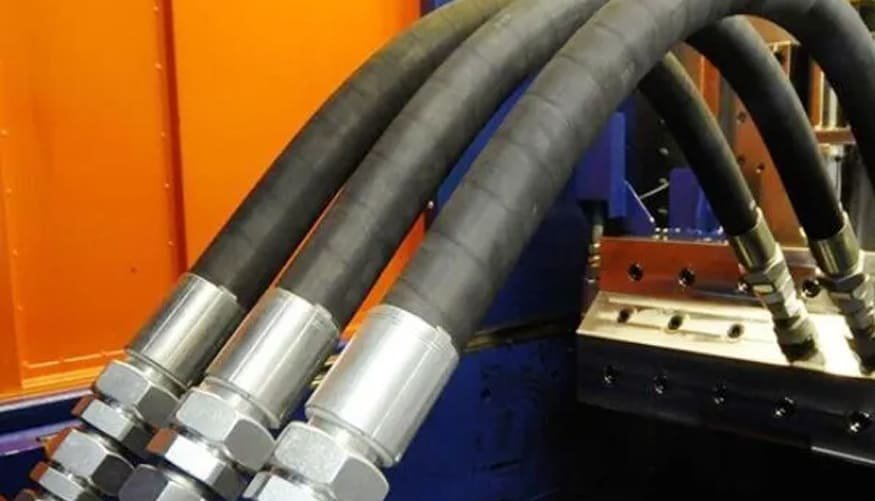

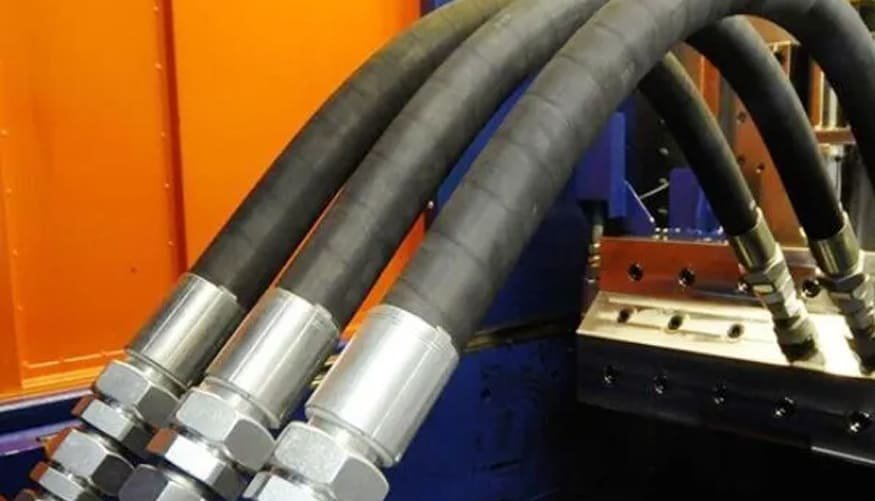

A hydraulic hose has three main parts:

- Inner Tube: This carries the oil or fluid. It’s usually made of strong rubber.

- Reinforcement Layer: Steel wire or woven fabric gives the hose its strength.

- Outer Cover: This protects the hose from heat, Produse chimice, and damage.

Many hoses are built to meet SAE or ISO standards. These tell you how much pressure or heat a hose can handle — something wholesalers should always check before selling.

How to Make Hydraulic Hoses with Fittings

Here’s how the process works step by step:

- Measure the Hose: Mark where you’ll cut.

- Cut It Cleanly: Use a saw made for rubber hoses.

- Attach the Fittings: Put a little lubricant on the fittings and slide them into the hose.

- Crimp the Hose: Use a hydraulic hose crimper or hydraulic hose making machine to lock the fittings in place.

- Inspectați-vă munca: Make sure the fittings are tight and even.

If you’re just starting out, a hydraulic hose making kit can help you practice before moving to larger production.

What Pipes Can Be Used for Hydraulic Lines?

Most hydraulic lines are made from steel, stainless steel, or rubber hoses. These materials can handle high pressure and last a long time. Avoid using copper pipes — they cause the fluid inside to oxidize, which damages the system over time.

Testing and Quality Inspection

Hose undergoes testing before leaving the factory or being used to ensure its safety and durability. Testing includes pressure testing (checking for leaks) and burst testing (checking its pressure resistance).

Hbkinglin Hydraulic Hose Manufacture also conducts long-term testing to ensure the hoses can withstand thousands of uses.

This step is crucial for wholesalers, ensuring that the hydraulic hoses you sell are safe and durable products.

Troubleshooting Common Hydraulic Hose Problems

Sometimes problems arise, such as loose rubber, scurgeri, or cracks. This often occurs when hydraulic hoses are not crimped correctly. Always check for problems before selling or installing hydraulic hoses.

For minor issues, you can use a hydraulic hose repair kit, but for major problems, replace the hose with a new one.

Rezumat

Manufacturing hydraulic hoses requires meticulous work, robust materials, and thorough testing. Understanding how hoses are manufactured makes it easier to select the best products and provide reliable advice to your customers.