Jeśli kiedykolwiek korzystałeś z węży hydraulicznych, będziesz wiedział, że istnieje wiele różnych typów. W tym przewodniku, I’ll help you understand the differences between single-braided and double-braided hoses so you can easily choose the right hose for your application.

Single braided hydraulic hose has one layer of steel wire, which makes it flexible and good for medium pressure jobs. Double braided hose has two layers of wire, which makes it stronger and better for high pressure systems. You’ll want single braided hoses when you need flexibility and low cost, and double braided hoses when you need strength and longer lift.

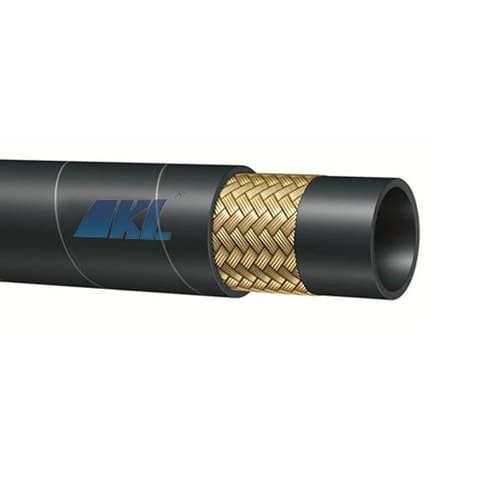

What is a single braided hydraulic hose?

Single braided hydraulic hose has three main parts. inside, there’s rubber tube that caddies oil or fluid. around that, there’s one layer of steel wire braid that keeps the hose strong under pressure. Then there’s the outer cover, which protects it from weather, olej, i nosić

You’ll usually see single braided hoses labeled SAE 1001AT or EN 853 1SN. These hoses are very flexible and easy to install, especially when you’re working in small spaces or tight machinery

Korzyść

- It’s cheaper than double braided hose

- It’s easy to handle and bend

- It works well for medium pressure systems

Disadvantage

- It can’t handle super high pressure.

- It might wear out faster in rough environments.

If your hydraulic hoses are used in equipment such as tractors, wózki widłowe, or small construction tools, then a single braided hydraulic hose is usually sufficient.

What is a double braided hydraulic hose?

Double braided hydraulic hose looks similar to the single one, but it has two layers of steel wire braid instead of one. Those two layers give you more strength, better pressure resistance, and extra protection from damage.

double braided hoses usually follow SAE 100R2AT or EN 583 2SN standerds. they’re perfect when you’re dealing with heavy duty machines or high pressure systems

Korzyść

- It handles very high pressure safely.

- It lasts longer and resists wear.

- It works great in tough environments.

Disadvantage

- It’s less flexible and harder to bend.

- It costs more and weighs more

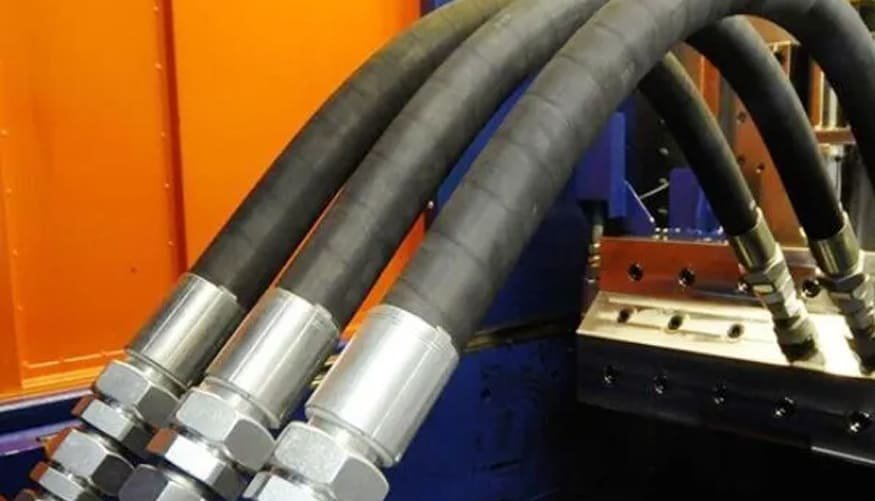

If you are using it on large excavators, dump trucks, or factory machinery, you will need to use double-braided hoses for better safety and performance.

What is the difference between single and double braided hose?

When you compare single and double braided hoses, there are six main things you’ll notice.

- Reinforcement Layers: Single-layer braided hoses have only one layer of steel wire, while double-layer braided hoses have two. The second layer of steel wire gives the hose greater strength, allowing it to withstand higher pressures.

- Ocena ciśnienia: Single-layer braided hoses are suitable for medium pressures, typically up to around 3,000 psi. Double-layer braided hoses can withstand much higher pressures, typically exceeding 6,000 psi.

- Elastyczność: Single-layer braided hoses are easier to bend and are better suited for confined spaces. Double-layer braided hoses are stronger but more rigid, thus requiring more installation space.

- Trwałość: The extra braid in double-layer braided hoses effectively prevents friction, wibracja, and external damage. If your hose is frequently dragged on the ground or used in harsh environments, double-layer braided hoses are the better choice.

- Cost and Weight: Single-layer braided hoses are lighter and cheaper, while double-layer braided hoses are heavier and more expensive. Jednakże, double-layer braided hoses have a longer lifespan and are more cost-effective in the long run.

- Application scenarios: Single-layer braided hoses are ideal for operations requiring flexibility and operating at low or moderate pressure. Jednakże, double-layer braided hoses should be selected when safety, odporność na ciśnienie, and service life are critical.

How to Choose Single-Strand Braided Hose and Double-Strand Braided Hose

When choosing the right hydraulic hose, you should consider the following:

- Operating Pressure: Check your system pressure level. Use single-strand braided cables for low-pressure environments and double-strand braided cables for high-pressure environments.

- Zakres temperatur: Most hydraulic hoses can withstand temperatures from -40°C to +100°C, but always check your system’s actual operating temperature range. If the ambient temperature is particularly high, choose a hose with a heat-resistant synthetic rubber outer layer.

- Elastyczność: If your hose needs to be moved frequently or used in confined spaces, choose a single-strand braided hose. If you need stability under load, choose double-strand braided hoses, which maintain their shape even under pressure.

- Abrasion and External Conditions: Outdoor or harsh environments accelerate hose wear. Choose double-strand braided hoses or add protective sleeves to protect against abrasion, żwir, and UV radiation.

- Koszt: If price is more important than strength, single-strand braided hoses are more economical. Jednakże, if you prioritize long-term value, double-strand braided hoses are a better choice.

Często zadawane pytania

Co jest lepsze: single braid or double braid?

That depends on your needs. Single braided hoses are easier to handle and cheaper, but double braided hoses are stronger and last longer under pressure.

What materials are used in braided hoses?

Most have a rubber inner tube, steel wire reinforcement, and a rubber outer layer to protect against oil and weather.

How long do braided hydraulic hoses last?

Usually between 5 I 7 lata, depending on how often you use them and the conditions they’re in.

Are wire braided hoses better than thermoplastic ones?

Wire braided hoses can take more heat and pressure, but thermoplastic hydraulic hoses are lighter and don’t rust — good for mobile or chemical systems.

What standards should you know?

The most common ones are SAE 100R1/R2, EN 853 1SN/2SN, I ISO 1436. These help make sure the hose meets safety and performance rules.

Streszczenie

Understanding the differences between single-layer and double-layer braided hoses will help you choose the appropriate hose for your work needs. If you are unsure which hydraulic hose is best suited for your application, Prosimy o kontakt. We are a professional manufacturer of hydraulic hoses and can meet your various needs.