Silicone hoses are popular for high-performance and industrial applications, but questions about porosity remain. If you are a wholesaler, doing product selection or customer inquiries, here is some information about silicone hoses to help you better serve your customers.

Standard silicone hoses are porous to gases, water vapor, and some oils. This permeability makes them unsuitable for use with fuels or petroleum unless they are lined with fluorosilicone. While they are heat and chemical-resistant, their porous structure allows oil mist to enter. That’s why proper application and lining selection are important in wholesale and industrial supply.

Let’s take a look at how silicone hose compares to other materials, when to use it, and what your customers need to know.

Is silicone hose permeable to water or air?

Yes. Because silicone hoses are porous, any water vapor and gas can slowly pass through, especially under pressure or high temperatures. But this is so slight that it is almost negligible.

Is silicone hose porous compared to polyethylene?

Silicone is more porous than polyethylene or other plastics. This porosity is well documented in scientific and medical settings. Oils and certain chemicals can even be absorbed into the hose walls over time.

If your customers require low reactivity and high inertness, polyethylene or PTFE tubing may be a better choice.

How does silicone permeability compare to rubber and butyl?

Silicone is 30 times more permeable than natural rubber and 400 times more permeable than butyl.

Can silicone hoses handle fuel or oil?

No, fuel and oil will seep into silicone and cause silicone tubing to fail over time. This is why you often hear of “oil-soaked” silicone hoses failing.

If your customers need to handle petroleum-based products, use fluorosilicone-lined hoses. Fluorosilicone-lined hoses are specifically designed for oil-resistant applications.

Why Fluorosilicone Lined Hoses Are Important to Wholesalers

Fluorosilicone adds a protective inner layer to silicone hoses. This significantly reduces permeability and makes the hose resistant to oil, fuel, and other chemicals.

For wholesalers, stocking these versions helps satisfy more demanding industrial buyers, especially in areas such as racing, aerospace, or high-performance automotive.

Make sure your listing clearly states whether the hose is lined or unlined—it’s a detail your customers will thank you for.

EPDM vs. Silicone: Which is Better for Radiator Applications?

EPDM rubber hoses are widely used in OEM systems. They are cheaper, less porous, and adequate for most standard engines.

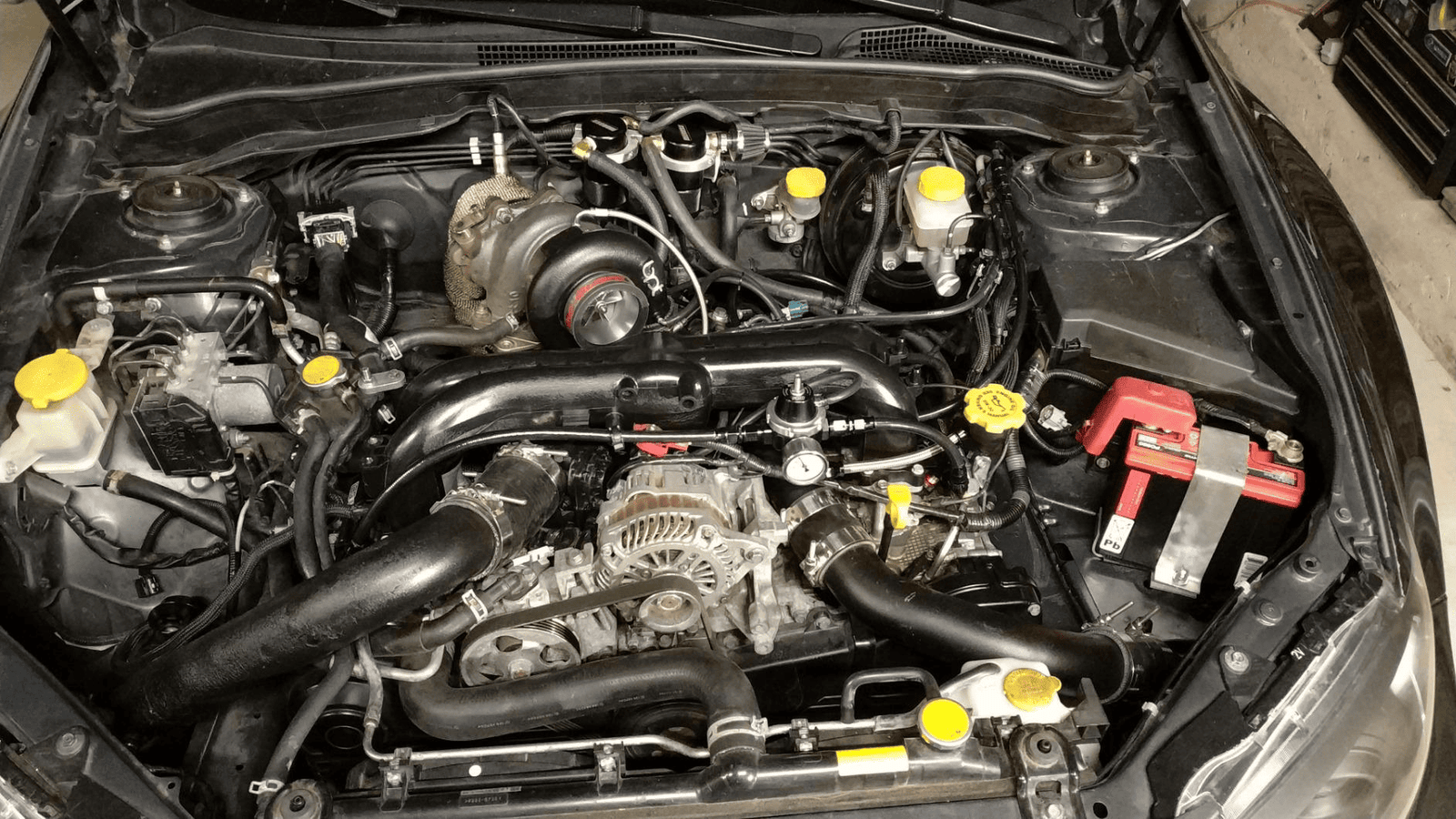

On the other hand, silicone hoses are highly heat-resistant and durable, making them ideal for high-performance or modified vehicles.

Silicone vs. Rubber: Which Hose Material Has Less Porosity?

Rubber hoses, especially EPDM, have less porosity than silicone. They are better at holding liquids and gases, especially in cooling systems and fuel lines.

However, rubber hoses degrade faster when exposed to heat or UV rays. On the other hand, silicone hoses can be used in hot environments for a long time. For wholesalers, it is helpful to make recommendations based on customer requirements.

When to use silicone hoses despite the porosity issue?

Silicone hoses are still the best choice when:

- Extreme temperature resistance is required

- Not used in oil fuel or high-volatile material systems

- An aesthetic, attractive appearance is required (e.g., custom engine compartments)

- Long service life and better cost performance in the long run

- They are well suited for racing, HVAC systems, marine applications, and food-grade environments, with the appropriate lining.