Système de contrôle de la qualité

Nos normes élevées

Nos produits adhèrent aux normes strictes de qualité des produits de l'ISO 9001:2015 et IATF 16949:2016.

Système de gestion de la qualité

Notre site de production met strictement en œuvre IATF16949, ISO 9001 normes. Nous effectuons un contrôle qualité à chaque étape des matières premières aux produits finis, et sont supervisés par notre personnel d'inspection de la qualité.

Spécifications précises

De la conception, dessin, production, inspection de qualité, emballage et livraison, la qualité n'est pas compromise à chaque étape, et la tolérance du diamètre de la chambre à air a été contrôlée au moins +-0,1 mm. 100% Inspection d'usine

Service personnalisé

Nous prenons en charge les services OEM et ODM, et peut personnaliser en fonction des différents besoins des clients, fournir des solutions de tubes en silicone qui répondent aux spécifications spéciales et aux normes industrielles. Que ce soit la taille, couleur, dureté, etc., nous pouvons répondre avec flexibilité

Personnalisez votre produit

Nos produits ont été vendus partout dans le monde, y compris plus de 120 pays et régions en Europe, Amérique du Nord, Amérique du Sud, Asie, Australie, le Moyen-Orient, etc.. Nos tuyaux en silicone ont également reçu des éloges de nombreux clients.

Capacités de test

À hbkinglin, nous utilisons des équipements de test avancés pour garantir la durabilité et les performances de nos produits. Nos tests incluent:

Test à basse température

Testez les tuyaux en silicone pour vérifier leur flexibilité et leurs performances à des températures extrêmement basses.. Assurez-vous que les tuyaux restent fonctionnels et ne se fissurent pas ou ne deviennent pas cassants dans les environnements froids..

Essai de traction

Teste la résistance à la traction et les propriétés d’allongement des matériaux silicones. Il mesure la pression que le matériau peut supporter avant de s'étirer et de se casser., garantissant que le tuyau en silicone peut résister aux pressions auxquelles il sera confronté dans les applications réelles.

Test de pression d'éclatement

Testez la pression maximale qu'un tuyau en silicone peut supporter avant d'éclater. Garantit que les flexibles fonctionnent de manière fiable dans les environnements à haute pression tels que les systèmes automobiles.

Test de résistance à haute température

Test des tuyaux en silicone pour la résistance aux températures élevées. Les tuyaux sont exposés à des températures élevées pour garantir qu'ils ne se dégradent pas ou ne perdent pas leurs performances dans des conditions de température difficiles..

Testeur de dureté

Mesurez la dureté des matériaux en silicone pour vous assurer qu'ils répondent aux spécifications requises. La dureté d'un tuyau affecte sa durabilité et sa flexibilité dans diverses applications.

Chambre d'essai de vieillissement

Tests de durabilité à long terme et de résistance au vieillissement dû à des facteurs environnementaux tels que les rayons UV, ozone et humidité. Assurer au tuyau en silicone une longue durée de vie sans dégradation.

Test de compression

Mesure la capacité du silicone à reprendre sa forme initiale après avoir été comprimé pendant une longue période. Garantit que le tuyau est flexible et résistant dans les applications où il est comprimé à plusieurs reprises.

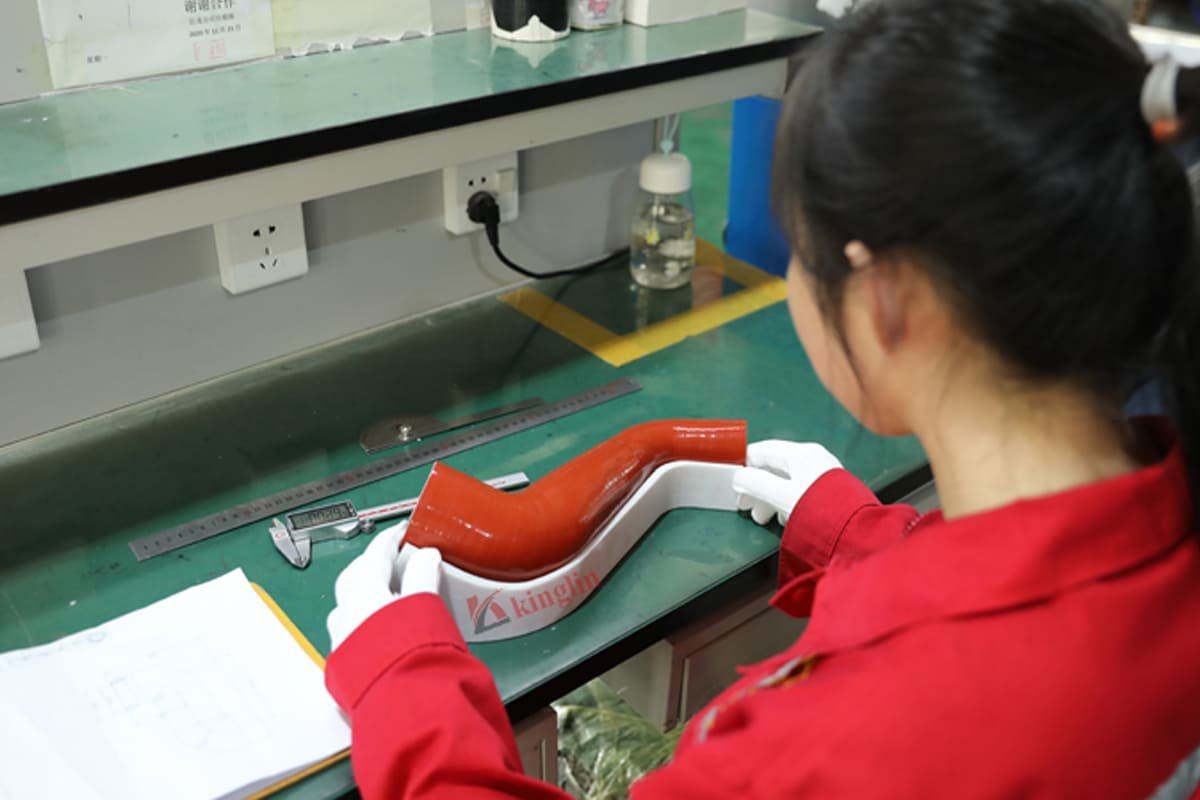

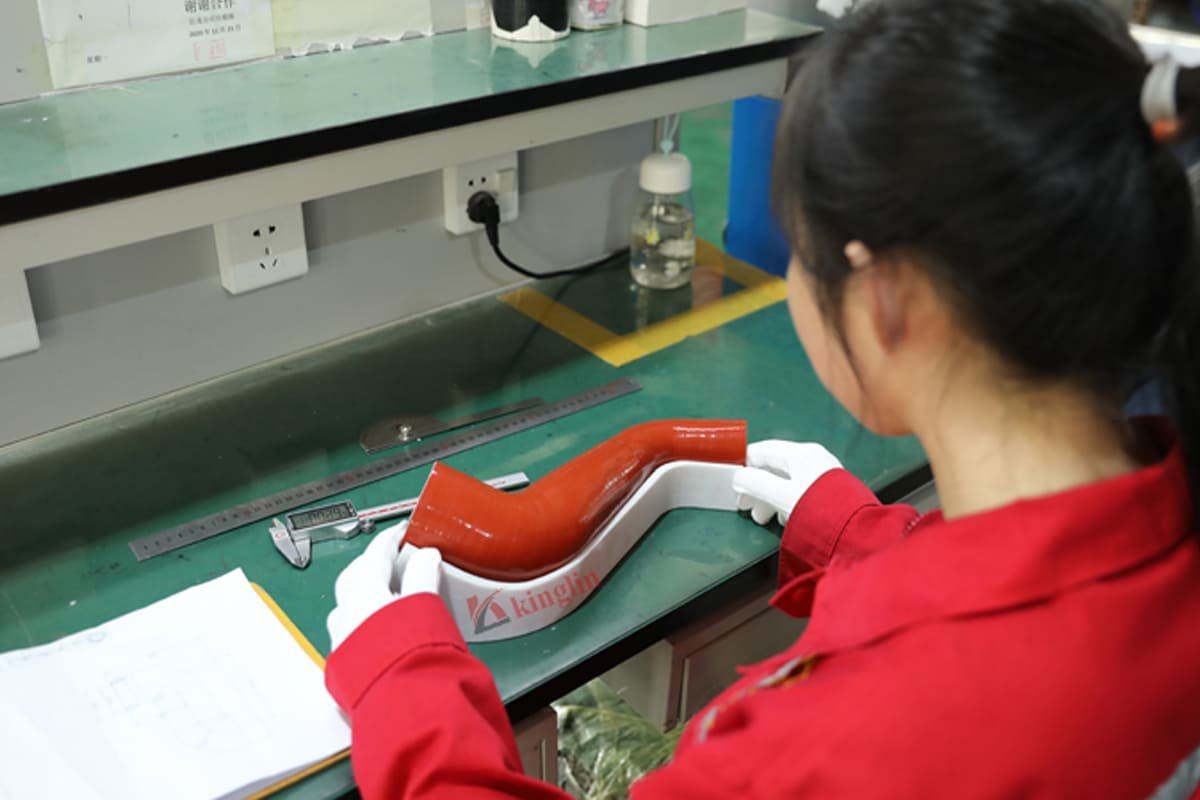

Instruments de mesure dimensionnelle

Mesurez avec précision les diamètres intérieur et extérieur, épaisseur de paroi, et autres dimensions critiques des tuyaux en silicone. Assurez-vous que le tuyau répond aux spécifications exactes exigées par vos clients.

Contrôle qualité rigoureux à chaque étape

Le contrôle qualité est intégré à chaque étape de notre production. De la sélection des matières premières à l'emballage final, notre ligne de production suit un processus strict pour garantir que chaque tuyau en silicone répond aux normes les plus élevées. Notre équipe dédiée au contrôle de la qualité effectue des contrôles ponctuels et des évaluations approfondies tout au long du processus pour éviter tout défaut..

Inspection des matières premières

Assurez-vous que le silicone brut et tout autre matériau utilisé dans la production répondent aux spécifications requises avant d'entrer dans le processus de fabrication..

Contrôle qualité en cours de processus

Surveiller la production à différentes étapes pour identifier et corriger les défauts dès le début du processus de fabrication.

Tests de produits semi-finis

Inspecter les tuyaux après les étapes initiales de production pour garantir qu'ils répondent aux normes de performance avant un traitement ultérieur..

Test du produit final

S'assurer que les produits finaux répondent à toutes les performances, sécurité, et les exigences du client avant d'être approuvé pour l'emballage.

Inspection des emballages

S'assurer que le processus d'emballage maintient la qualité du produit et évite les dommages pendant l'expédition

Contrôle de qualité avant expédition

S'assurer que les produits expédiés dans ce lot répondent aux exigences de commande et aux normes de qualité du client

Notre perspicacité d'usine

Questions fréquemment posées

Si vous avez des questions, N'hésitez pas à nous contacter afin que nous puissions vous servir un meilleur produit ou service. Nous vous accueillons également chaleureusement pour partager votre expertise, Créons un espace ouvert pour l'échange et l'apprentissage pour tous ceux qui sont passionnés par l'industrie du tuyau de silicone.

E-mail:service@hbkinglin.com

Téléphone:008615613933397

Contactez-nous pour un échantillon gratuit

Si vous avez des questions ou demandez un devis, Veuillez nous envoyer un message. Nos experts vous reviendront à l'intérieur 14 heures et vous aider à choisir le bon tuyau.